![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

Full-automatic water softener

产品概述

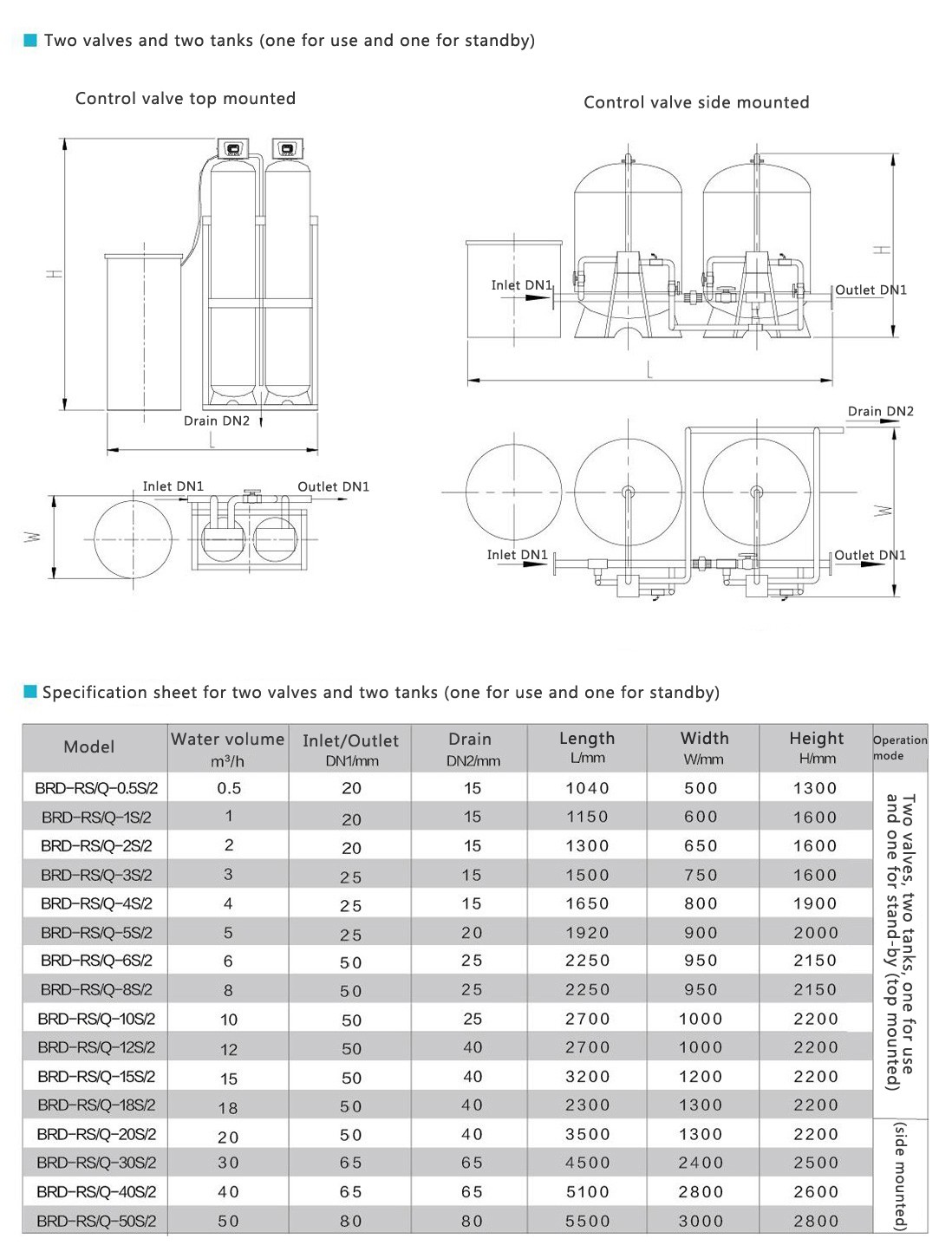

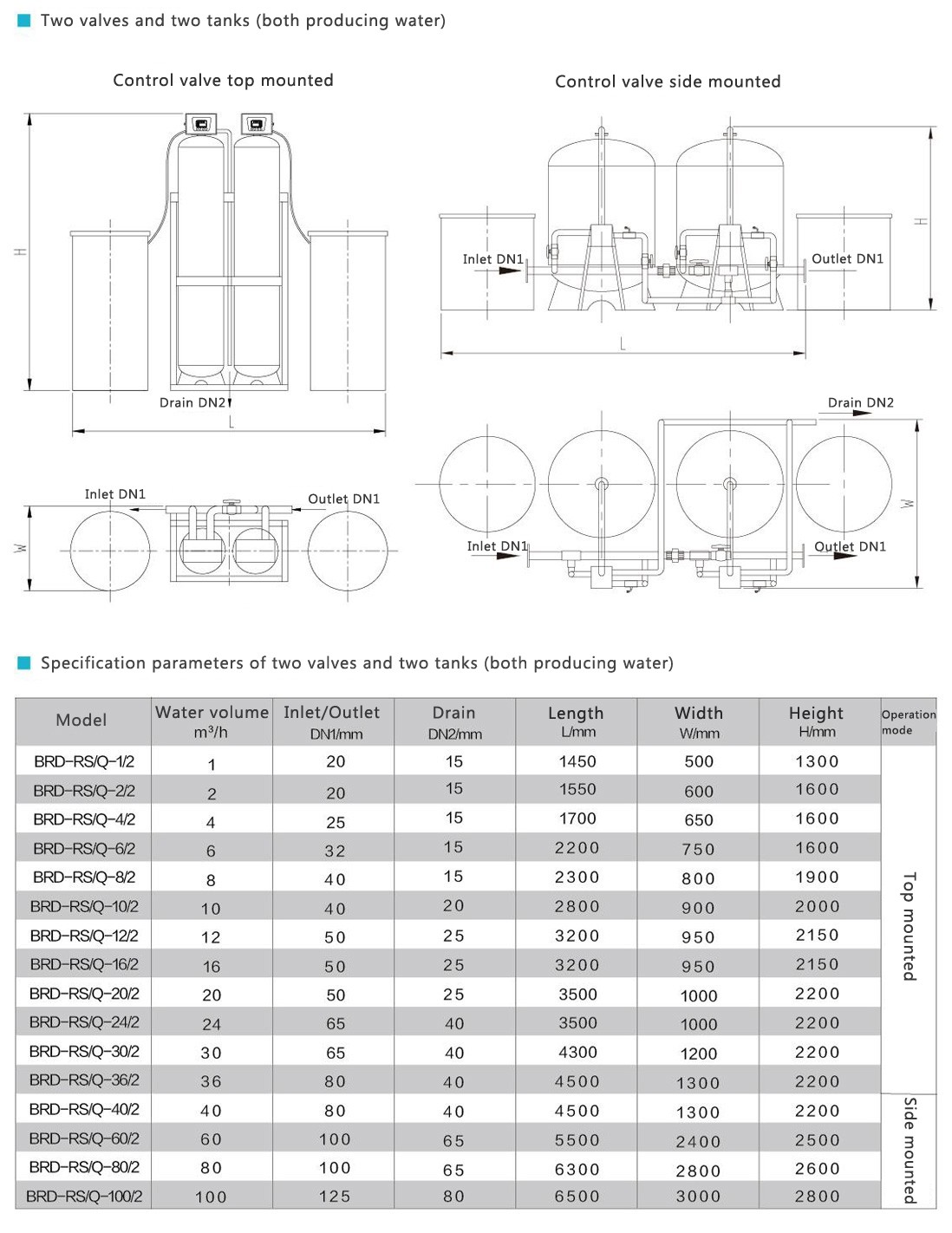

我公司生产的软化水设备以软化閥及控制器为核心,配用相应的树脂罐、盐箱、管道等构成全自动软化水设备。使软化、反洗、吸盐、慢洗、快洗、盐箱注水等全过程实现自动化。全自动软水器应用于工业锅、熱交换大型中央空调、宾馆占、食品工业、洗衣印染、医疗卫生等行为时间控制量控制型按照供水方式不同,分为单单罐、双阀双罐(一用双阀双罐(共同产水)等多种组合形式,满足用户不同。

Product overview

The softened water equipment takes softener valve and controller as the core, and is equipped with corresponding resin tank, salt tank, pipeline, etc. to form a full-automatic softened water equipment. The whole process of softening, backwashing, salt absorption, slow washing, fast washing and salt tank water injection can be automated. The automatic water softener is used in industrial boiler, heat exchange large-scale central air conditioning, hotel occupancy, food industry, laundry printing and dyeing, medical and health care and other behavior time control types. According to different water supply modes, it can be divided into single tank, double valve and double tank (one with double valve and double tank (common water production) and other combination forms to meet different users.

工作原理

水的硬度主要由其中的阳离子:钙(Ca2+)、镁子构成。当含有硬度的原水通过交换器的树贈层日、镁离子被树脂吸附,同时释放出钠离子,这样交换器内流出的水就是去掉了硬度离子的软化水,当树脂吸附钙、镁的饱和度后,出水的硬度增大,此时软水器会按照预定的程序自动进行失效树脂的再生工作,利用较高)通过树脂,使失效的树脂重新恢复至钠型树脂。

Working principle

The hardness of water is mainly composed of cations: Ca2 +, MgO. When the raw water containing hardness is absorbed by resin through the tree layer of the exchanger, and magnesium ions are released at the same time, so that the water flowing out of the exchanger is softened water with the hardness ions removed. When the resin absorbs the saturation of calcium and magnesium, the hardness of the water increases. At this time, the softener will automatically regenerate the failed resin according to the predetermined procedure, and use the higher) resin to make The failed resin was restored to sodium resin.

产品特点

1)自动化程度高,运行工况稳定,按预先设置的程序,自动完成软化再生等循环过程。日常运行除加盐外无须人工操。

2)高效率低能耗,运行费用经济。由于软水器整体设计合理,使树脂的交换能力得以充分发挥,设备采用射流式吸盐,替代盐泵,降低了能耗。

3)设备结构紧凑,占地面积小,节省了基建投,安装、调试、使用简便易行,运行部件性能稳定。

4)选型灵活,可根据需要选择单罐、双罐、多罐系统;时间、流量控制方式;同时再生、交替再生等运行方式

5)性能可靠,出水水质稳定。

6)抗蚀性强,罐体采用玻璃钢及工程塑料或不锈钢制作,可避免再生剂对设备的腐蚀。

Product characteristics

1) High degree of automation, stable operation conditions, according to the pre-set procedures, automatic completion of softening regeneration and other cycle processes. No manual operation except adding salt for daily operation

2) High efficiency, low energy consumption and economic operation cost. Because the overall design of the water softener is reasonable, the exchange capacity of the resin can be brought into full play. The equipment adopts the jet type salt suction to replace the salt pump, which reduces the energy consumption

3) The equipment is compact in structure, small in floor area, saving capital construction investment, easy to install, debug and use, and stable in performance of operating parts.

4) Flexible selection, single tank, double tank and multi tank system, time and flow control mode, simultaneous regeneration, alternative regeneration and other operation modes can be selected as required

5) Reliable performance, stable effluent quality.

6) It has strong corrosion resistance. The tank body is made of glass fiber reinforced plastic, engineering plastics or stainless steel, which can avoid the corrosion of regenerant to the equipment.