![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

一、Product Introduction

Product overview:

THJS graphite chemical process centrifugal pump is our independent research and development of new design of high temperature resistance, acid resistance, corrosion resistance, chemical process of centrifugal pump, using graphite material, which has excellent heat resistance, corrosion resistance, and has very good wear resistance and excellent impact resistance, can adapt to the different the working condition of the pump, the pump which has the advantages of corrosion resistance and wear resistance, the use of a wide range, especially suitable for high solid content, high temperature and corrosive medium strong acid (the weight concentration is less than 20%, solid solid particles with a diameter less than 1.0mm).

Product advantages:

1. THJS graphite chemical process of centrifugal pump is our company according to the JB/T technical design of nonmetal pump manufacturing plate type chemical process of centrifugal pump based on 8688-2013 standard, has the advantages of high temperature resistance, corrosion resistance, abrasion resistance, high mechanical strength, high efficiency and energy saving etc.;

2. pump body, impeller, cover, seal box, shaft sleeve, protective sleeve, throttle ring, impeller cover flow of the main material used impregnated graphite (carbon fiber, glass fiber, copper and other materials) for different working conditions selection.

3. pump shell graphite material, thickness 20mm-50mm, clamp design, metal support, limiting the full plastic pump shell heat graphite axial expansion and compression permanent deformation of axial compression, overcome the pump body deformation, shrinkage deformation leads to unstable mechanical properties the shortcomings of using the CFD computer fluid mechanics design of hydraulic components module design and molding, should be able to withstand the high speed and high pressure liquid erosion, and can withstand the effects of instantaneous thermal shock, has high anti cavitation ability, size precision, smooth flow, good interchangeability, effectively improve the operation stability of graphite corrosion resistant pump.

4. impeller using CFD computational fluid dynamics design of hydraulic components of the module design and precision casting, ensure the reliable transmission of torque, the closed or semi open structure, channel optimization design, high efficiency, low NPSHR value, good interchangeability, ensure the stability of the flow and lift pump;

5. pump seal for the container type, double end resistance to high temperature, corrosion resistance, wear-resistant machine seal, can transport containing particles, crystallization medium. Configurable API682 standard seal layout and flushing scheme;

6. machine sealing ring, shaft sleeve and sliding bearing adopt high wear resistance and temperature resistant crystal silicon carbide material. The utility model has the advantages of high strength, good wear resistance, good self resistance and strong corrosion resistance, and effectively ensures the service life of the pump;

7. rear pull design, no disassembly of the pipe, easy maintenance;

8. horizontal installation, compact structure, international standard design, interchangeable with standard chemical centrifugal pump, convenient for users to change and use.

Product use:

It is especially suitable for high temperature hydrochloric acid, high temperature sulfuric acid, high temperature mixed acid and strong acid high temperature medium;

Non-ferrous metal smelting industry: all kinds of acid liquid is especially suitable for lead, zinc, gold, silver, copper, manganese, cobalt and rare earth hydrometallurgy, corrosive slurry, slurry (with filter) electrolyte, sewage and other media delivery. Phosphorus fertilizer: dilute acid and sulfuric acid liquor, wastewater containing silica gel, fluosilicic acid, phosphoric acid slurry conveying medium; chemical and other enterprises: a variety of sulfuric acid, hydrochloric acid, alkaline, oil liquid or slurry post. Titanium dioxide, iron powder production, the production of various dyes, pigments, non-metallic mineral processing industries; chlor alkali industry: hydrochloric acid, liquid electrolyte, etc.; environmental protection industry, water treatment industry: pure water, high pure water, sewage, sewage, sewage (leather electroplating wastewater, papermaking wastewater, electronic textile wastewater, food wastewater and domestic wastewater. Pharmaceutical wastewater, waste gas and waste) spray dust control center of the absorption cycle pump; iron and steel enterprises: sulfuric acid and hydrochloric acid pickling system with impurity position, the thermal power sewage; wet desulfurization circulating pump can also apply to: alkali, acid, corrosive post; coal chemical industry, coal conveying in corrosive liquid coal slurry; coal washing pump with other similar conditions related industry.

Performance range:

Design pressure: 1.6mpa;

Caliber: ~ 300mm;

Flow rate: 5 ~ 1600m3/h;

Lift: 5 ~ 80m

Power: 0.75 ~ 250kw;

Temperature: less than or equal to 180 DEG c

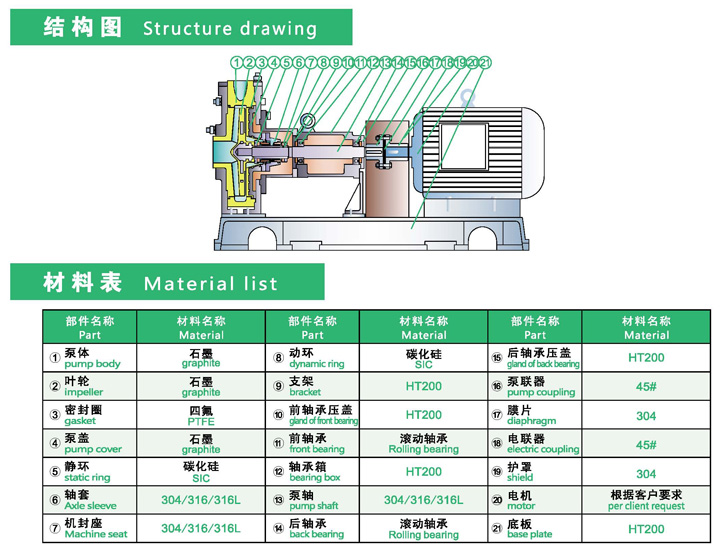

二、Structure drawing

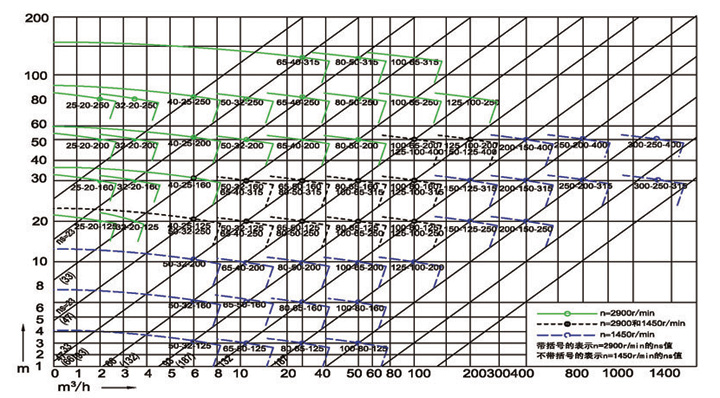

三、Performance Curve

| Type | Speed r/min |

Flow m3/h |

Head m |

Efficiency % |

NPSH m |

InletXOutlet mm |

Motor power |

Weight |

| THJS25-20-125 | 2900 | 2 | 20.5 | 25 | 2.5 | 25×20 | 1.1 | 75 |

| 3.2 | 20 | 32 | 2.5 | |||||

| 5.5 | 18 | 46 | 2.5 | |||||

| 1450 | 0.75 | 5.4 | 15 | 2.5 | 0.37 | 55 | ||

| 1 | 5 | 17 | 2.5 | |||||

| 1.6 | 4.6 | 21 | 3 | |||||

| THJS25-20-160 | 2900 | 1.5 | 34.3 | 19 | 2.5 | 25×20 | 1.5 | 80 |

| 2 | 32 | 22 | 2.5 | |||||

| 3.2 | 29.6 | 25 | 3 | |||||

| 1450 | 0.75 | 8.5 | 16 | 2.5 | 0.37 | 55 | ||

| 1 | 8 | 18 | 2.5 | |||||

| 1.6 | 7.5 | 24 | 3 | |||||

| THJS25-20-200A | 2900 | 1.5 | 42 | 28 | 2.5 | 25×20 | 3 | 124 |

| 2 | 40 | 32 | 2.5 | |||||

| 3.2 | 38 | 30 | 3 | |||||

| 1450 | 0.75 | 10.5 | 15 | 2.5 | 0.55 | 90 | ||

| 1 | 10 | 18 | 2.5 | |||||

| 1.6 | 9.5 | 24 | 3 | |||||

| THJS25-20-200 | 2900 | 1.5 | 52.5 | 18 | 2.5 | 25×20 | 4 | 124 |

| 2 | 50 | 20 | 2.5 | |||||

| 3.2 | 48 | 22 | 3 | |||||

| 1450 | 0.75 | 13.1 | 15 | 2.5 | 0.75 | 90 | ||

| 1 | 12.5 | 18 | 2.5 | |||||

| 1.6 | 12 | 24 | 3 | |||||

| THJS25-20-250A | 2900 | 1.5 | 62 | 26 | 2.5 | 25×20 | 7.5 | 225 |

| 2 | 60 | 30 | 2.5 | |||||

| 3.2 | 58 | 28 | 3 | |||||

| 1450 | 0.75 | 15.5 | 15 | 2.5 | 1.5 | 118 | ||

| 1 | 15 | 18 | 2.5 | |||||

| 1.6 | 14.5 | 24 | 3 | |||||

| THJS25-20-250B | 2900 | 1.5 | 72 | 26 | 2.5 | 25×20 | 5.5 | 225 |

| 2 | 70 | 30 | 2.5 | |||||

| 3.2 | 68 | 28 | 3 | |||||

| 1450 | 0.75 | 18 | 15 | 2.5 | 1.1 | 118 | ||

| 1 | 17.5 | 18 | 2.5 | |||||

| 1.6 | 17 | 24 | 3 | |||||

| THJS25-20-250 | 2900 | 2 | 80 | 12 | 2.5 | 25×20 | 7.5 | 225 |

| 3.6 | 80 | 18 | 2.5 | |||||

| 5.5 | 78.5 | 26 | 3 | |||||

| 1450 | 0.75 | 20.5 | 11 | 2.5 | 1.5 | 118 | ||

| 1 | 20 | 16 | 2.5 | |||||

| 1.6 | 19.5 | 24 | 3 | |||||

| THJS32-20-125 | 2900 | 2 | 22 | 25 | 2.5 | 32×20 | 1.5 | 75 |

| 3.2 | 20 | 32 | 2.5 | |||||

| 5.5 | 18.5 | 46 | 3 | |||||

| 1450 | 1 | 5.4 | 24 | 2.5 | 0.55 | 45 | ||

| 1.6 | 5 | 22 | 2.5 | |||||

| 2.75 | 4.6 | 22.5 | 3 | |||||

| THJS32-20-160 | 2900 | 2 | 34.3 | 25 | 2.5 | 32×20 | 2.2 | 98 |

| 3.2 | 32 | 24 | 2.5 | |||||

| 5.5 | 29.6 | 21.5 | 3 | |||||

| 1450 | 1 | 8.5 | 18 | 2.5 | 0.55 | 55 | ||

| 1.6 | 8 | 22 | 2.5 | |||||

| 2.75 | 7.5 | 24.5 | 3 | |||||

| THJS32-20-200A | 2900 | 2 | 42 | 32 | 2.5 | 32×20 | 4 | 140 |

| 3.2 | 40 | 36 | 2.5 | |||||

| 5.5 | 38 | 34 | 3 | |||||

| 1450 | 1 | 10.5 | 25 | 2.5 | 0.75 | 78 | ||

| 1.6 | 10 | 28 | 2.5 | |||||

| 2.75 | 9.5 | 26 | 3 | |||||

| THJS32-20-200 | 2900 | 2 | 52.5 | 22 | 2.5 | 32×20 | 4 | 140 |

| 3.2 | 50 | 26 | 2.5 | |||||

| 5.5 | 48 | 28.5 | 3 | |||||

| 1450 | 1 | 13.1 | 15 | 2.5 | 0.75 | 78 | ||

| 1.6 | 12.5 | 18 | 2.5 | |||||

| 2.75 | 12 | 19.5 | 3 | |||||

| THJS32-20-250A | 2900 | 2 | 62 | 26 | 2.5 | 32×20 | 7.5 | 160 |

| 3.2 | 60 | 30 | 2.5 | |||||

| 5.5 | 58 | 28 | 3 | |||||

| 1450 | 1 | 15.5 | 15 | 2.5 | 1.1 | 98 | ||

| 1.6 | 15 | 18 | 2.5 | |||||

| 2.75 | 14.5 | 24 | 3 | |||||

| THJS32-20-250B | 2900 | 2 | 72 | 26 | 2.5 | 32×20 | 7.5 | 160 |

| 3.2 | 70 | 30 | 2.5 | |||||

| 5.5 | 68 | 28 | 3 | |||||

| 1450 | 1 | 18 | 15 | 2.5 | 1.1 | 98 | ||

| 1.6 | 17.5 | 18 | 2.5 | |||||

| 2.75 | 17 | 24 | 3 | |||||

| THJS32-20-250 | 2900 | 2 | 82 | 16 | 2.5 | 32×20 | 11 | 160 |

| 3.2 | 80 | 20 | 2.5 | |||||

| 5.5 | 78.5 | 23 | 3 | |||||

| 1450 | 1 | 20.5 | 15 | 2.5 | 1.5 | 98 | ||

| 1.6 | 20 | 18 | 2.5 | |||||

| 2.75 | 19.5 | 24 | 3 | |||||

| THJS40-25-125 | 2900 | 6.3 | 22 | 30 | 2.5 | 40×25 | 2.2 | 75 |

| 8 | 32 | 31 | 2.5 | |||||

| 10 | 30 | 32 | 3 | |||||

| 1450 | 2.2 | 5.4 | 26 | 2.5 | 0.55 | 42 | ||

| 3.2 | 5 | 28 | 2.5 | |||||

| 4.2 | 4.6 | 32 | 3 | |||||

| THJS40-25-160 | 2900 | 6.3 | 32 | 30 | 2.5 | 40×25 | 3 | 124 |

| 8 | 32 | 31 | 2.5 | |||||

| 10 | 30 | 32 | 3 | |||||

| 1450 | 2.2 | 8.5 | 23 | 2.5 | 0.55 | 78 | ||

| 3.2 | 8 | 25 | 2.5 | |||||

| 4.2 | 7.5 | 28 | 3 | |||||

| THJS40-25-200A | 2900 | 4.4 | 42 | 26 | 2.5 | 40×25 | 4 | 170 |

| 6.3 | 40 | 33 | 2.5 | |||||

| 8.3 | 38 | 32 | 3 | |||||

| 1450 | 2.2 | 10.5 | 25 | 2.5 | 0.55 | 102 | ||

| 3.2 | 10 | 28 | 2.5 | |||||

| 4.2 | 9.5 | 26 | 3 | |||||

| THJS40-25-200 | 2900 | 6.3 | 52.5 | 20 | 2.5 | 40×25 | 5.5 | 170 |

| 8 | 50 | 23 | 2.5 | |||||

| 10 | 48 | 30 | 3 | |||||

| 1450 | 2.2 | 13.1 | 25 | 2.5 | 1.1 | 102 | ||

| 3.2 | 12.5 | 28 | 2.5 | |||||

| 4.2 | 12 | 26 | 3 | |||||

| THJS40-25-250A | 2900 | 4.4 | 62 | 24 | 2.5 | 40×25 | 7.5 | 255 |

| 6.3 | 60 | 28 | 2.5 | |||||

| 8.3 | 58 | 28 | 3 | |||||

| 1450 | 2.2 | 15.5 | 20 | 2.5 | 1.1 | 155 | ||

| 3.2 | 15 | 24 | 2.5 | |||||

| 4.2 | 14.5 | 22 | 3 | |||||

| THJS40-25-250B | 2900 | 4.4 | 72 | 24 | 2.5 | 40×25 | 11 | 255 |

| 6.3 | 70 | 28 | 2.5 | |||||

| 8.3 | 68 | 28 | 3 | |||||

| 1450 | 2.2 | 18 | 20 | 2.5 | 1.5 | 155 | ||

| 3.2 | 17.5 | 24 | 2.5 | |||||

| 4.2 | 17 | 22 | 3 | |||||

| THJS40-25-250 | 2900 | 4.4 | 82 | 24 | 2.5 | 40×25 | 11 | 255 |

| 6.3 | 80 | 28 | 2.5 | |||||

| 8.3 | 78.5 | 28 | 3 | |||||

| 1450 | 2.2 | 20.5 | 20 | 2.5 | 1.5 | 155 | ||

| 3.2 | 20 | 24 | 2.5 | |||||

| 4.2 | 19.5 | 22 | 3 | |||||

| THJS50-32-125 | 2900 | 7.5 | 22 | 43 | 2 | 50×32 | 3 | 110 |

| 12.5 | 20 | 51 | 2 | |||||

| 15 | 18.5 | 49 | 2.5 | |||||

| 1450 | 3.75 | 5.4 | 40 | 2 | 0.55 | 55 | ||

| 6.3 | 5 | 45 | 2 | |||||

| 7.5 | 4.6 | 42 | 2.5 | |||||

| THJS50-32-160 | 2900 | 7.5 | 34.3 | 35 | 2 | 50×32 | 4 | 135 |

| 12.5 | 32 | 47 | 2 | |||||

| 15 | 29.6 | 47 | 2.5 | |||||

| 1450 | 3.72 | 8.5 | 30 | 2 | 0.55 | 68 | ||

| 6.3 | 8 | 40 | 2 | |||||

| 7.5 | 7.5 | 40 | 2.5 | |||||

| THJS50-32-200A | 2900 | 7.5 | 42 | 28 | 2 | 50×32 | 5.5 | 180 |

| 12.5 | 40 | 39 | 2 | |||||

| 15 | 38 | 43 | 2.5 | |||||

| 1450 | 3.7 | 10.5 | 23 | 2 | 0.75 | 170 | ||

| 6.3 | 10 | 33 | 2 | |||||

| 7.5 | 9.5 | 36 | 2.5 | |||||

| THJS50-32-200 | 2900 | 7.5 | 52.5 | 28 | 2 | 50×32 | 7.5 | 180 |

| 12.5 | 50 | 40 | 2 | |||||

| 15 | 48 | 48 | 2.5 | |||||

| 1450 | 3.7 | 13.1 | 22 | 2 | 1.1 | 170 | ||

| 6.3 | 12.5 | 33 | 2 | |||||

| 7.5 | 12 | 40 | 2.5 | |||||

| THJS50-32-250A | 2900 | 7.5 | 62 | 23 | 2 | 50×32 | 7.5 | 255 |

| 12.5 | 60 | 33 | 2 | |||||

| 15 | 58 | 36.5 | 2.5 | |||||

| 1450 | 3.75 | 15.5 | 17 | 2 | 1.1 | 155 | ||

| 6.3 | 15 | 27 | 2 | |||||

| 7.5 | 14.5 | 31 | 2.5 | |||||

| THJS50-32-250B | 2900 | 7.5 | 72 | 23 | 2 | 50×32 | 15 | 255 |

| 12.5 | 70 | 33 | 2 | |||||

| 15 | 68 | 36.5 | 2.5 | |||||

| 1450 | 3.75 | 18 | 17 | 2 | 2.2 | 155 | ||

| 6.3 | 17.5 | 27 | 2 | |||||

| 7.5 | 17 | 31 | 2.5 | |||||

| THJS50-32-250 | 2900 | 7.5 | 82 | 23 | 2 | 50×32 | 18.5 | 255 |

| 12.5 | 80 | 33 | 2 | |||||

| 15 | 78.5 | 36.5 | 2.5 | |||||

| 1450 | 3.75 | 20.5 | 17 | 2 | 2.2 | 155 | ||

| 6.3 | 20 | 30 | 2 | |||||

| 7.5 | 19.5 | 33 | 2.5 | |||||

| THJS65-50-125 | 2900 | 15 | 21.8 | 46 | 2 | 65×50 | 4 | 135 |

| 25 | 20 | 61 | 2 | |||||

| 30 | 18.5 | 67 | 2.5 | |||||

| 1450 | 7.5 | 5.35 | 46 | 2 | 0.55 | 75 | ||

| 12.5 | 5 | 61 | 2 | |||||

| 15 | 4.7 | 67 | 2.5 | |||||

| THJS65-50-160 | 2900 | 15 | 35 | 46 | 2 | 65×50 | 5.5 | 155 |

| 25 | 32 | 56 | 2 | |||||

| 30 | 30 | 65 | 2.5 | |||||

| 1450 | 7.5 | 8.8 | 40 | 2 | 1.1 | 145 | ||

| 12.5 | 8 | 51 | 2 | |||||

| 15 | 7.2 | 60 | 2.5 | |||||

| THJS65-40-200A | 2900 | 15 | 42 | 41 | 2 | 65×40 | 7.5 | 210 |

| 25 | 40 | 52 | 2 | |||||

| 30 | 38 | 53.5 | 2.5 | |||||

| 1450 | 7.5 | 10.5 | 35 | 2 | 1.5 | 132 | ||

| 12.5 | 10 | 46 | 2 | |||||

| 15 | 9.5 | 47.5 | 2.5 | |||||

| THJS65-40-200 | 2900 | 15 | 53 | 35 | 2 | 65×40 | 11 | 210 |

| 25 | 50 | 51 | 2 | |||||

| 30 | 47 | 48 | 2.5 | |||||

| 1450 | 7.5 | 13.2 | 30 | 2 | 1.5 | 132 | ||

| 12.5 | 12.5 | 46 | 2 | |||||

| 15 | 11.8 | 42 | 2.5 | |||||

| THJS65-40-250A | 2900 | 15 | 62 | 34 | 2 | 65×40 | 15 | 360 |

| 25 | 60 | 46 | 2 | |||||

| 30 | 58 | 50 | 2.5 | |||||

| 1450 | 7.5 | 15.5 | 28 | 2 | 2.2 | 240 | ||

| 12.5 | 15 | 39 | 2 | |||||

| 15 | 14.5 | 43 | 2.5 | |||||

| THJS65-40-250B | 2900 | 15 | 72 | 34 | 2 | 65×40 | 18.5 | 360 |

| 25 | 70 | 46 | 2 | |||||

| 30 | 68 | 50 | 2.5 | |||||

| 1450 | 7.5 | 18 | 28 | 2 | 3 | 240 | ||

| 12.5 | 17.5 | 39 | 2 | |||||

| 15 | 17 | 43 | 2.5 | |||||

| THJS65-40-250 | 2900 | 15 | 82 | 33 | 2 | 65×40 | 22 | 360 |

| 25 | 80 | 48 | 2 | |||||

| 30 | 78 | 50 | 2.5 | |||||

| 1450 | 7.5 | 21 | 28 | 2 | 4 | 240 | ||

| 12.5 | 20 | 43 | 2 | |||||

| 15 | 19.4 | 45 | 2.5 | |||||

| THJS65-40-315A | 2900 | 15 | 105 | 28 | 2.5 | 65×40 | 30 | 480 |

| 25 | 100 | 39 | 2.5 | |||||

| 30 | 98 | 42.5 | 3 | |||||

| 1450 | 7.5 | 26.2 | 22 | 2.5 | 5.5 | 260 | ||

| 12.5 | 25 | 33 | 2.5 | |||||

| 15 | 24.5 | 37 | 3 | |||||

| THJS65-40-315 | 2900 | 15 | 127 | 28 | 2.5 | 65×40 | 37 | 480 |

| 25 | 125 | 39 | 2.5 | |||||

| 30 | 123 | 42.5 | 3 | |||||

| 1450 | 7.5 | 32.3 | 22 | 2.5 | 5.5 | 260 | ||

| 12.5 | 32 | 33 | 2.5 | |||||

| 15 | 31.7 | 37 | 3 | |||||

| THJS80-65-125 | 2900 | 30 | 22.5 | 52 | 3 | 80×65 | 7.5 | 195 |

| 50 | 20 | 65 | 3 | |||||

| 60 | 18 | 70 | 3.5 | |||||

| 1450 | 15 | 5.6 | 50 | 2.5 | 1.1 | 125 | ||

| 25 | 5 | 64 | 2.5 | |||||

| 30 | 4.5 | 68 | 3 | |||||

| THJS80-65-160 | 2900 | 30 | 36 | 60 | 2.5 | 80×65 | 11 | 228 |

| 50 | 32 | 64 | 2.5 | |||||

| 60 | 29 | 53 | 3 | |||||

| 1450 | 15 | 9 | 58 | 2.5 | 1.5 | 145 | ||

| 25 | 8 | 62 | 2.5 | |||||

| 30 | 7.2 | 50 | 3 | |||||

| THJS80-50-200A | 2900 | 30 | 42 | 53 | 2.5 | 80×50 | 15 | 250 |

| 50 | 40 | 63 | 2.5 | |||||

| 60 | 38 | 62 | 3 | |||||

| 1450 | 15 | 10.5 | 44 | 2.5 | 2.2 | 155 | ||

| 25 | 10 | 57 | 2.5 | |||||

| 30 | 9.5 | 58 | 3 | |||||

| THJS80-50-200 | 2900 | 30 | 53 | 53 | 2.5 | 80×50 | 15 | 250 |

| 50 | 50 | 63 | 2.5 | |||||

| 60 | 47 | 55 | 3 | |||||

| 1450 | 15 | 13.2 | 49 | 2.5 | 3 | 155 | ||

| 25 | 12.5 | 57 | 2.5 | |||||

| 30 | 11.8 | 48 | 3 | |||||

| THJS80-50-250A | 2900 | 30 | 62 | 44 | 2.5 | 80×50 | 22 | 480 |

| 50 | 60 | 57 | 2.5 | |||||

| 60 | 58 | 59 | 3 | |||||

| 1450 | 15 | 15.5 | 39 | 2.5 | 3 | 370 | ||

| 25 | 15 | 51 | 2.5 | |||||

| 30 | 14.5 | 52.5 | 3 | |||||

| THJS80-50-250B | 2900 | 30 | 72 | 44 | 2.5 | 80×50 | 30 | 480 |

| 50 | 70 | 57 | 2.5 | |||||

| 60 | 68 | 59 | 3 | |||||

| 1450 | 15 | 18 | 39 | 2.5 | 4 | 400 | ||

| 25 | 17.5 | 51 | 2.5 | |||||

| 30 | 17 | 52.5 | 3 | |||||

| THJS80-50-250 | 2900 | 30 | 84 | 48 | 2.5 | 80×50 | 37 | 480 |

| 50 | 80 | 56 | 2.5 | |||||

| 60 | 75 | 50 | 3 | |||||

| 1450 | 15 | 21 | 39 | 2.5 | 5.5 | 400 | ||

| 25 | 20 | 51 | 2.5 | |||||

| 30 | 18.8 | 52.5 | 3 | |||||

| THJS80-50-315A | 2900 | 30 | 105 | 39 | 2.5 | 80×50 | 45 | 560 |

| 50 | 100 | 51 | 2.5 | |||||

| 60 | 98 | 52.5 | 3 | |||||

| 1450 | 15 | 26.2 | 35 | 2.5 | 7.5 | 476 | ||

| 25 | 25 | 46 | 2.5 | |||||

| 30 | 24.5 | 47.5 | 3 | |||||

| THJS80-50-315 | 2900 | 30 | 128 | 39 | 2.5 | 80×50 | 55 | 560 |

| 50 | 125 | 51 | 2.5 | |||||

| 60 | 123 | 52.5 | 3 | |||||

| 1450 | 15 | 32.5 | 35 | 2.5 | 11 | 476 | ||

| 25 | 32 | 46 | 2.5 | |||||

| 30 | 31.5 | 47.5 | 3 | |||||

| THJS100-80-125 | 2900 | 60 | 24 | 64 | 4 | 100×80 | 11 | 245 |

| 100 | 20 | 65 | 4.5 | |||||

| 120 | 16.5 | 63 | 5 | |||||

| 1450 | 30 | 6 | 60 | 2.5 | 1.5 | 198 | ||

| 50 | 5 | 64 | 2.5 | |||||

| 60 | 4 | 63 | 3 | |||||

| THJS100-80-160 | 2900 | 60 | 36 | 60 | 3.5 | 100×80 | 18.5 | 250 |

| 100 | 32 | 70 | 4 | |||||

| 120 | 28 | 65 | 5 | |||||

| 1450 | 30 | 9.2 | 58 | 2 | 3 | 192 | ||

| 50 | 8 | 69 | 2.5 | |||||

| 60 | 6.8 | 68 | 3.5 | |||||

| THJS100-65-200A | 2900 | 60 | 42 | 63 | 3 | 100×65 | 30 | 480 |

| 100 | 40 | 72 | 3.6 | |||||

| 120 | 38 | 71 | 4.8 | |||||

| 1450 | 30 | 10.5 | 60 | 2 | 4 | 180 | ||

| 50 | 10 | 68 | 2 | |||||

| 60 | 9.5 | 63 | 2.5 | |||||

| THJS100-65-200 | 2900 | 60 | 54 | 63 | 3 | 100×65 | 37 | 256 |

| 100 | 50 | 68 | 3.6 | |||||

| 120 | 47 | 56 | 4.8 | |||||

| 1450 | 30 | 13.5 | 60 | 2 | 5.5 | 246 | ||

| 50 | 12.5 | 68 | 2 | |||||

| 60 | 11.8 | 63 | 2.5 | |||||

| THJS100-65-250A | 2900 | 60 | 62 | 57 | 3.5 | 100×65 | 37 | 382 |

| 100 | 60 | 68 | 3.8 | |||||

| 120 | 58 | 67 | 4.8 | |||||

| 1450 | 30 | 15.5 | 50 | 2 | 5.5 | 342 | ||

| 50 | 15 | 63 | 2 | |||||

| 60 | 14.5 | 64 | 2.5 | |||||

| THJS100-65-250B | 2900 | 60 | 72 | 57 | 3.5 | 100×65 | 45 | 480 |

| 100 | 70 | 68 | 3.8 | |||||

| 120 | 68 | 67 | 4.8 | |||||

| 1450 | 30 | 18 | 50 | 2 | 5.5 | 360 | ||

| 50 | 17.5 | 63 | 2 | |||||

| 60 | 17 | 64 | 2.5 | |||||

| THJS100-65-250 | 2900 | 60 | 87 | 60 | 3.5 | 100×65 | 45 | 550 |

| 100 | 80 | 68 | 3.8 | |||||

| 120 | 74.5 | 67 | 4.8 | |||||

| 1450 | 30 | 21.3 | 50 | 2 | 7.5 | 420 | ||

| 50 | 20 | 65 | 2 | |||||

| 60 | 19 | 64 | 2.5 | |||||

| THJS100-65-315A | 2900 | 60 | 105 | 48 | 3 | 100×65 | 55 | 670 |

| 100 | 100 | 62 | 3.6 | |||||

| 120 | 98 | 64 | 4.2 | |||||

| 1450 | 30 | 26.2 | 44 | 2 | 7.5 | 580 | ||

| 50 | 25 | 58 | 2 | |||||

| 60 | 24.5 | 60 | 2.5 | |||||

| THJS100-65-315 | 2900 | 60 | 133 | 63 | 3 | 100×65 | 75 | 670 |

| 100 | 125 | 65 | 3.6 | |||||

| 120 | 118 | 62 | 4.2 | |||||

| 1450 | 30 | 34 | 60 | 2 | 11 | 580 | ||

| 50 | 32 | 64 | 2 | |||||

| 60 | 30 | 63 | 2.5 | |||||

| THJS125-100-200 | 2900 | 120 | 57.5 | 54 | 4.5 | 125×100 | 55 | 660 |

| 200 | 50 | 68 | 4.5 | |||||

| 240 | 44.5 | 61 | 5 | |||||

| 1450 | 60 | 14.5 | 59 | 2.5 | 11 | 540 | ||

| 100 | 12.5 | 72 | 2.5 | |||||

| 120 | 11 | 71 | 3 | |||||

| THJS125-100-250A | 2900 | 120 | 62 | 63 | 3.8 | 125×100 | 55 | 850 |

| 200 | 60 | 75 | 4.2 | |||||

| 240 | 58 | 74 | 5 | |||||

| 1450 | 60 | 15.5 | 59 | 2.5 | 11 | 660 | ||

| 100 | 15 | 72 | 2.5 | |||||

| 120 | 14.5 | 71 | 3 | |||||

| THJS125-100-250B | 2900 | 120 | 72 | 63 | 3.8 | 125×100 | 75 | 850 |

| 200 | 70 | 75 | 4.2 | |||||

| 240 | 68 | 74 | 5 | |||||

| 1450 | 60 | 18 | 59 | 2.5 | 15 | 660 | ||

| 100 | 17.5 | 72 | 2.5 | |||||

| 120 | 17 | 71 | 3 | |||||

| THJS125-100-250 | 2900 | 120 | 87 | 57 | 3.8 | 125×100 | 75 | 850 |

| 200 | 80 | 68 | 4.2 | |||||

| 240 | 72 | 67 | 5 | |||||

| 1450 | 60 | 21.5 | 56 | 2.5 | 15 | 660 | ||

| 100 | 20 | 62 | 2.5 | |||||

| 120 | 18.5 | 58 | 3 | |||||

| THJS125-100-315A | 1450 | 60 | 26.2 | 57 | 2.5 | 125×100 | 18.5 | 950 |

| 100 | 25 | 68 | 2.5 | |||||

| 120 | 24.5 | 67 | 3 | |||||

| THJS125-100-315 | 1450 | 60 | 33.5 | 66 | 2.5 | 125×100 | 22 | 950 |

| 100 | 32 | 77 | 2.5 | |||||

| 120 | 30.5 | 68 | 3 | |||||

| THJS125-100-400A | 1450 | 60 | 42 | 56 | 2.5 | 125×100 | 30 | 1050 |

| 100 | 40 | 62 | 2.5 | |||||

| 120 | 38 | 58 | 3 | |||||

| THJS125-100-400 | 1450 | 60 | 52 | 63 | 2.5 | 125×100 | 37 | 1050 |

| 100 | 50 | 75 | 2.5 | |||||

| 120 | 48.5 | 72 | 3 | |||||

| THJS150-125-250 | 1450 | 120 | 22.5 | 61 | 3 | 150×125 | 22 | 632 |

| 200 | 20 | 67 | 3 | |||||

| 240 | 17.5 | 63 | 3.5 | |||||

| THJS150-125-315 | 1450 | 120 | 34 | 72 | 2.5 | 150×125 | 45 | 700 |

| 200 | 32 | 74 | 2.5 | |||||

| 240 | 29 | 75 | 3 | |||||

| THJS150-125-400A | 1450 | 120 | 42 | 61 | 2.5 | 150×125 | 45 | 1180 |

| 200 | 40 | 70 | 2.8 | |||||

| 240 | 38 | 63 | 3.5 | |||||

| THJS150-125-400 | 1450 | 120 | 53 | 61 | 2.5 | 150×125 | 55 | 1180 |

| 200 | 50 | 70 | 2.8 | |||||

| 240 | 46 | 63 | 3.5 | |||||

| THJS200-150-250 | 1450 | 240 | 21.5 | 67 | 3.5 | 200×150 | 55 | 700 |

| 400 | 20 | 79 | 4.3 | |||||

| 460 | 17.5 | 77 | 5 | |||||

| THJS200-150-315 | 1450 | 240 | 37 | 67 | 3 | 200×150 | 75 | 1180 |

| 400 | 32 | 78 | 3.5 | |||||

| 460 | 28.5 | 75 | 4 | |||||

| THJS200-150-400A | 1450 | 240 | 42 | 67 | 3 | 200×150 | 90 | 1420 |

| 400 | 40 | 78 | 3.8 | |||||

| 460 | 38 | 75 | 4.5 | |||||

| THJS200-150-400 | 1450 | 240 | 55 | 68 | 3 | 200×150 | 110 | 1420 |

| 400 | 50 | 73 | 3.8 | |||||

| 460 | 45 | 77 | 4.5 | |||||

| THJS250-200-250 | 1450 | 600 | 22 | 78 | 4.1 | 250×200 | 55 | 1300 |

| 800 | 20 | 82 | 5 | |||||

| 960 | 16 | 81 | 6 | |||||

| THJS250-200-315 | 1450 | 600 | 34 | 76 | 4.8 | 250×200 | 90 | 2050 |

| 800 | 32 | 80 | 5.5 | |||||

| 960 | 28 | 79 | 6.4 | |||||

| THJS250-200-400A | 1450 | 600 | 42 | 59 | 3.5 | 250×200 | 110 | 2500 |

| 800 | 40 | 72 | 4.3 | |||||

| 960 | 38 | 71 | 5 | |||||

| THJS250-200-400 | 1450 | 600 | 54.5 | 59 | 3.5 | 250×200 | 160 | 2500 |

| 800 | 50 | 72 | 4.3 | |||||

| 960 | 39 | 71 | 5 | |||||

| THJS300-250-315 | 1450 | 1550 | 35 | 68 | 3.6 | 300×250 | 220 | 2980 |

| 1400 | 32 | 84 | 4.5 | |||||

| 1300 | 26 | 75 | 5.4 | |||||

| THJS300-250-400 | 1450 | 1550 | 55 | 65 | 4.1 | 300×250 | 250 | 5000 |

| 1400 | 50 | 78 | 5 | |||||

| 1300 | 42.5 | 75 | 6 |