![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

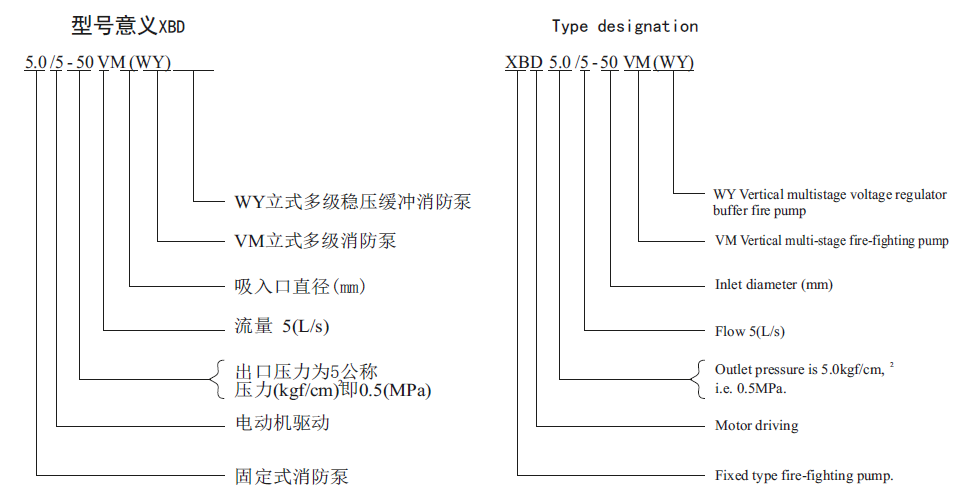

XBD-VM(WY) Series Vertical (Horizontal) Single-Stage Single-Suction Fire-Fighting Pump

产品概述

XBD系列消防泵是我公司根据市场对消防泵的实际需要及其特殊的使用要求,严格按照国家最新颁布的GB6245-2006《消防泵》标准而研制开发的新型消防产品。经国家消防装备质量监督检测中心检测,各项性能指标均达到或超过标准的要求,并获得国家消防产品认证证书。XBD系列分为立式单级、立式多级、便拆立式多级和卧式多级四种结构形式,以满足用户不同的使用需要。

Product introduction

XBD series fire-fighting pumps are a kind of new type fire-fighting products researched and developed in full compliance with the stateissued newly standard of GB6245-2006《Fire pumps》, according to the end-user's practicalneedsand special using requirements. The inspection of the state fire-fighting equipment quality supervising center shows its all kinds of performance indexes are upto or over the standard's requirements and it earned the certificate for fire-fighting products awarded by Shanghai city. XBD series of products can be divided into four kinds of different structures, including vertical single-grade, vertical mutil-grade, vertical mutil-grade with convenient dismantlement and horizontal multigrade,in order to gratify the different using requirements of clients.

产品用途

XBD系列消防泵主要用于各企事业单位、工程建设、高层大厦等固定消防系统中的消防栓灭火系统、自动喷淋灭火系统等,可供输送100℃以下不含固体颗粒的清水及物理化学性质类似于水的介质,又可用于消防、生活、生产共用给水系统及建筑、市政给排水等。

Product application

XBD series fire-fighting pumps are mainly used for the fixed fire hydrant fire-fighting system, automatic spraying fire-fighting system used by all sorts of organs, projects, high-floor buildings etc. and can be trans ferred with the clear water without solid grain under 100℃ or its equivalence, also be used for public-used water-providing system for firefighting,living, production, construction and municipality.

安装说明

1、安装时管路重量不得承受在泵体上,否则易损坏泵;

2、泵与电机是整体结构,出厂时已由厂家校正,所以安装时无须调整,因此安装十分方便;

3、安装时务必拧紧地脚螺栓,且每间隔一定时段应对泵进行检查防止其松动,以免泵启动时发生剧烈振动而影响泵的性能;

4、为了维护方便和使用安全,在泵的出口管路上安装一只调节阀及在出口附近安装一只压力表,对于高扬程的泵,为防止水锤,还应在出口闸阀前安装一只止回阀以防止突然断电等失去动力事故,从而确保水泵在最佳工况下运行;

5、泵用于有吸程的场合,应装有底阀,并且进口管道不应有过多的弯道,同时不得有漏气、漏水等现象,以免影响水泵的吸入能力;

6、为了不使杂质进入泵内而堵塞流道影响性能,应在泵进口前面安装过滤器;

7、应定期(一般为15天)试运行泵,运行时间为1小时左右,以防止紧急时刻抱轴卡死不能运行。

Installation instructions

1.Being installed, pumps should not bear the weight of the pipe system, or it is very easy to be damaged.

2.The pump is integrated with the motor, and is adjusted well by themanufacture before dispatch, so it's very convenient to be installedwithout any adjustment.

3.Doing its best to fasten the studs connecting with earth, when theend-user install the pump, and inspect them at an expected time ino-rderto prevent them from becoming flexible and avoid fiercely vibration to affect the pump's performances.

4.To a convenient maintenance and safe use, there be installed witha adjusting valve and pressure gauge at the outlet pipe and close to the outlet, for the highly-lifting pump, there should be installed with a check valve at front of the outlet gate valve in order to prevent the water hammer phenomenon yielded for sudden no power and to insure the pump runs in the best conditions.

5.In the situation that the pump used in sucking, and a floor valve should be installed at the inlet, and there should be no too many curv-ing channels, at the same time, there should be no phenomena of airleaking,water-leaking etc.

6.In order to let impurities not get into the pump and block the flowing channel and affect the performances, a strainer should be instal - led at front of the pump inlet.

7.Commissioning the pump at a firmed period ( usually in 15 days), running time is 1 hr. about to avoid the shaft is jammed in the urgent time.

起动与停车

启动前

1、用手转动联轴器,转子部件应无卡死现象

2、打开进口阀门、排气阀使水充满泵腔,然后关闭排气阀;

3、点动电机,确定转向是否正确;

运行

1、全开进口阀门,关闭出口管路阀门。

2、接通电源,当泵转速达到正常后,再打开出口管道阀门,并调节到所需的工况点;

3、观察泵运行后的有无异常情况,如有异常情况应立即停车检查,处理后再运行;

停 车

1、逐渐关闭出口阀门后,切断电源;

2、关闭进口阀门;

3、如环境温度低于0℃,应采取保暖措施。

Start up and shut down

Before start

1.turning the clutch by hand, there should be no jammedphenomenon at the turner position.

2.Opening the inlet valve and the vent valve, letting the water fillinto the pump's chamber, then closing the vent valve.

3.Clicking the switch of motor, and confirming whether the turningis right or not.

Running

1.Fully opening the inlet valves, and closing the valves of the outletpipe.

2.Connecting the power, Opening the v- alves of the outlet pipe andadjusting the needed working point when the turning velocity is normal.

3.Watching whether there exist abnormities or not, if yes, shouldthe pump be stopped and inspected before rerunning.Stop1.After turning off the outlet valves one by one, shutting off thepower.Stop

Stop

1.After turning off the outlet valves one by one, shutting off thepower.

2.Shutting off the inlet valves.

3.If the ambient temperature is below 0℃, some warm-keepingmeasures should be adopted.

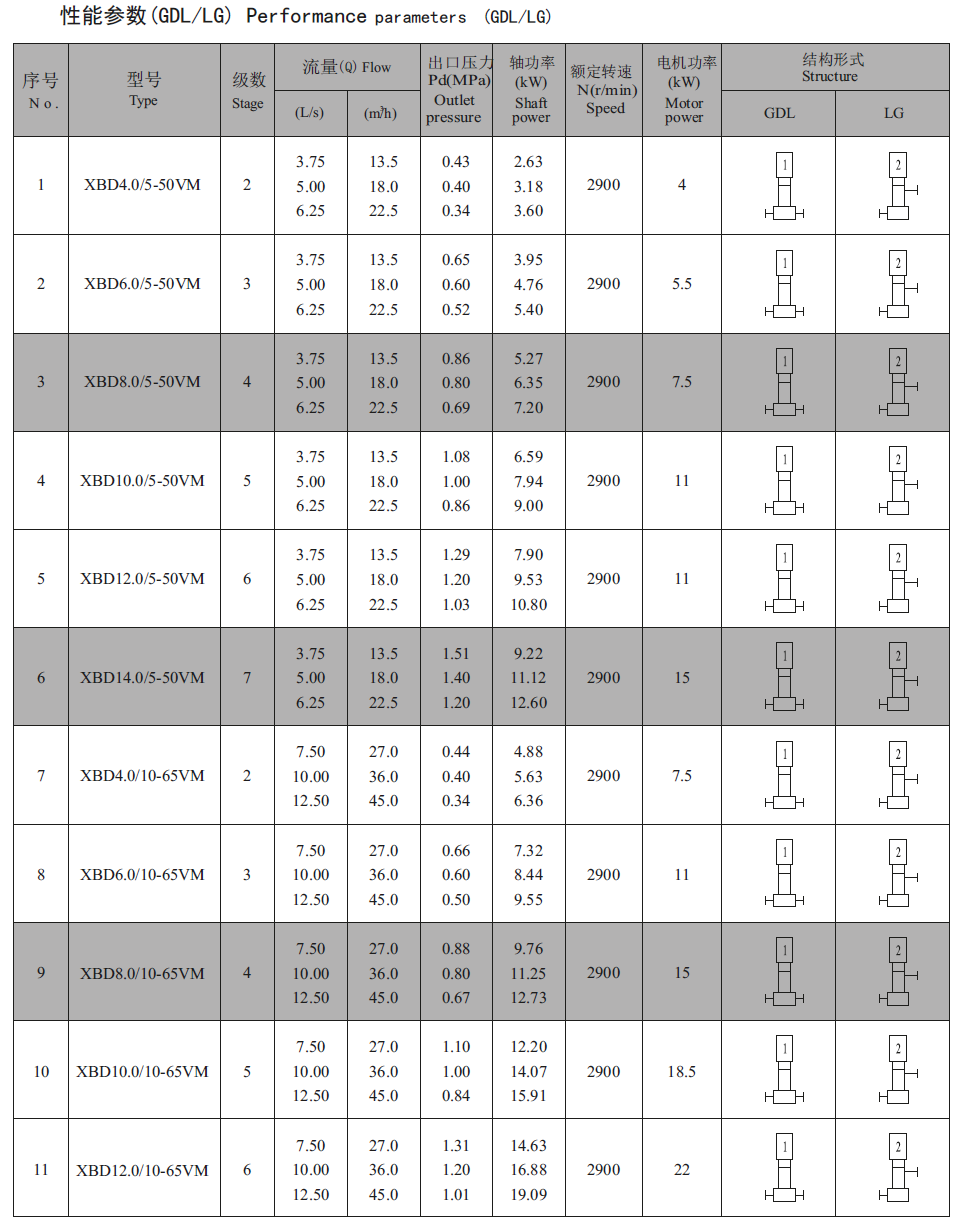

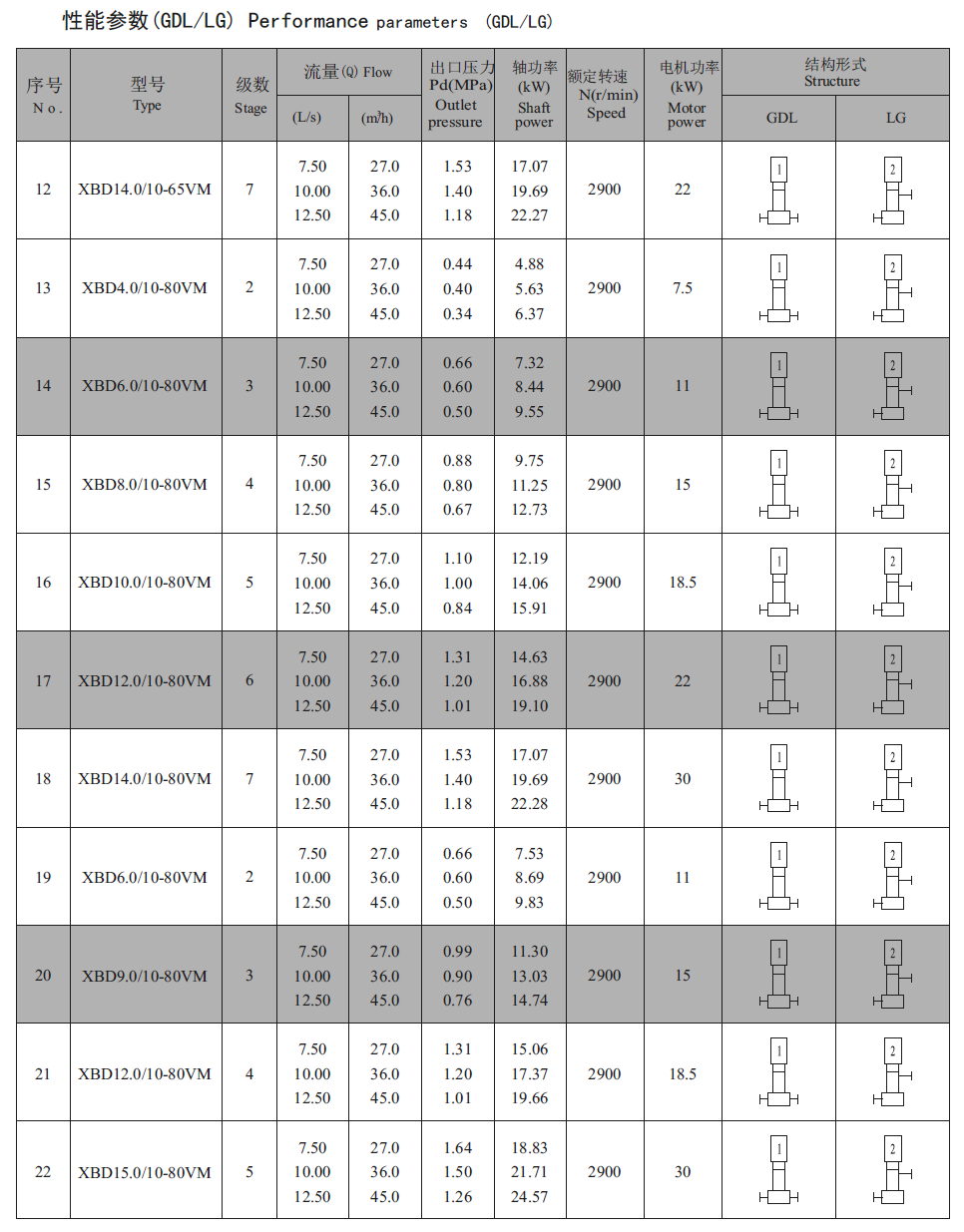

注:各种型号规格消防泵的性能曲线图见本公司的出厂检验报告。

Note: The fire-fighting pump's performance graph for all kinds of types and specifications are shown on our inspection reports.