![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

XBD-HY(HW) Series Horizontal Constant Pressure Fire-Fighting Pump

产品概述

XBD-HY(LW)系列卧式恒压消防泵是我公司根据市场需求而研制的适用于高层建筑消防给水和生活供水的新产品,是可靠、高品质的消防专用泵。其性能、技术条件符合国家标准GB6245-2006《消防泵性能要求和试验方法》标准的要求。

XBD-HY(LW)系列卧式恒压消防泵具有变流稳压的特点,即在全流量范围内,扬程变化不大,泵从零流量到所需最大流量范围内的变化时,其扬程变化在5%范围内,且小流量或零流量时不超压,从而避免了普通离心泵在消防现场中小流量时超压而大流量时供不上水的现象。大大提高了灭火效率及消防设备和消防人员的安全可靠性。

根据消防泵自身特点结合我公司情况。泵叶轮为开式,轴向力小,无口环,防止了锈蚀咬死现象。泵体、泵盖采用铸铁,叶轮根据用户要求采用不锈钢、青铜或其他耐腐蚀性材料制造。

Product introduction

XBD-HY(HW)series horizontal constant pressure fire-fighting pump is a kind of new product researched and manufactured by our company according to market demand. Applicable to fire-fighting and living water supply in high-rise constructions, it belongs to a special fire-fighting pump with reliable and high-quality nature. The performance and technical conditions accord with the requirements of National Standard GB6245-2006 Performance Requirements and Testing Method of Firefighting Pump.

XBD-HY(HW)series horizontal constant pressure fire-fighting pump enjoys variable flow and stable pressure. That is to say, within the scope of total flow, the range does not have great changes; once the pump

changes from flow zero to the limit within the needed maximum flow, the range change is within the scope of 5% and the pressure will not exceed in case of small flow or flow zero. All these characteristics have avoided the phenomenon of excessive pressure of ordinary centrifugal pump in medium and small flow but supply shortage in large flow and greatly upgraded the safety and reliability for fire-fighting efficiency, firefighting equipment and personnel.

According to the characteristics in the fire-fighting pump and by integrating the atual conditions of our company, the pump blade is open type with small axial force and without rings which have prevented the rusting and seizure. Cast iron is adopted for pump body and cover while nodular cast iron or bronze materials are adopted for blades according to users' requirements.

产品用途

XBD-HY(HW)系列卧式恒压消防泵主要适用于工业、民用建筑物消防系统(消防栓灭火系统、自动喷淋系统和水雾灭火系统)的给水,另外也可用于消防和生活(生产)共用的给水系统及建筑、市政、工矿、锅炉给水等各种场合。

Product application

XBD-HY(HW)series horizontal constant pressure fire-fighting pump is mainly applicable to the water supply of fire-fighting systems (firefighting hydrant system, automatic spraying system and water mist firefighting system) in the industrial and civil constructions. Furthermore, it can also be adopted for shared fire-fighting and living (production) water supply systems and the water supply systems in constructions,municipalities, mines and boilers.

工作条件

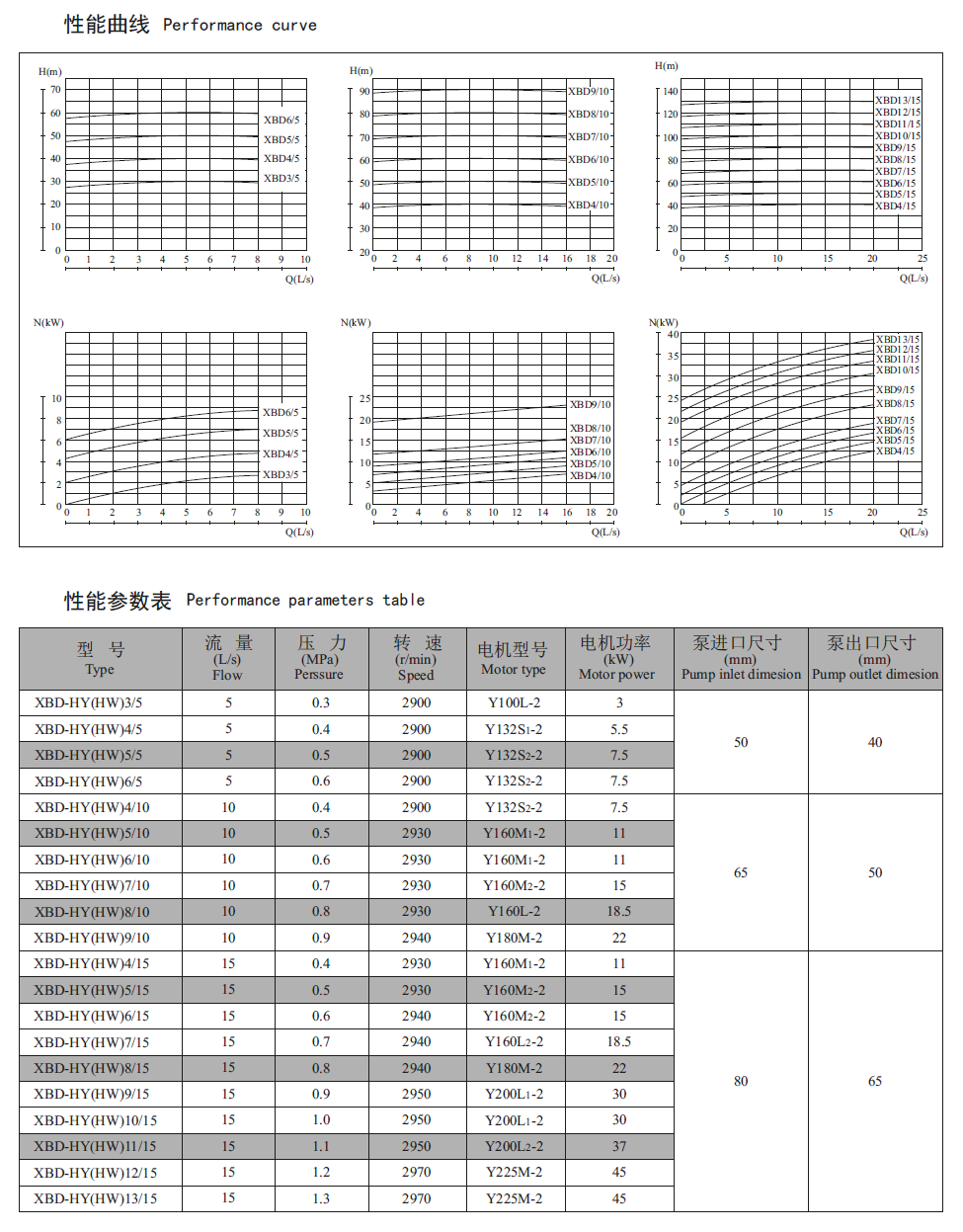

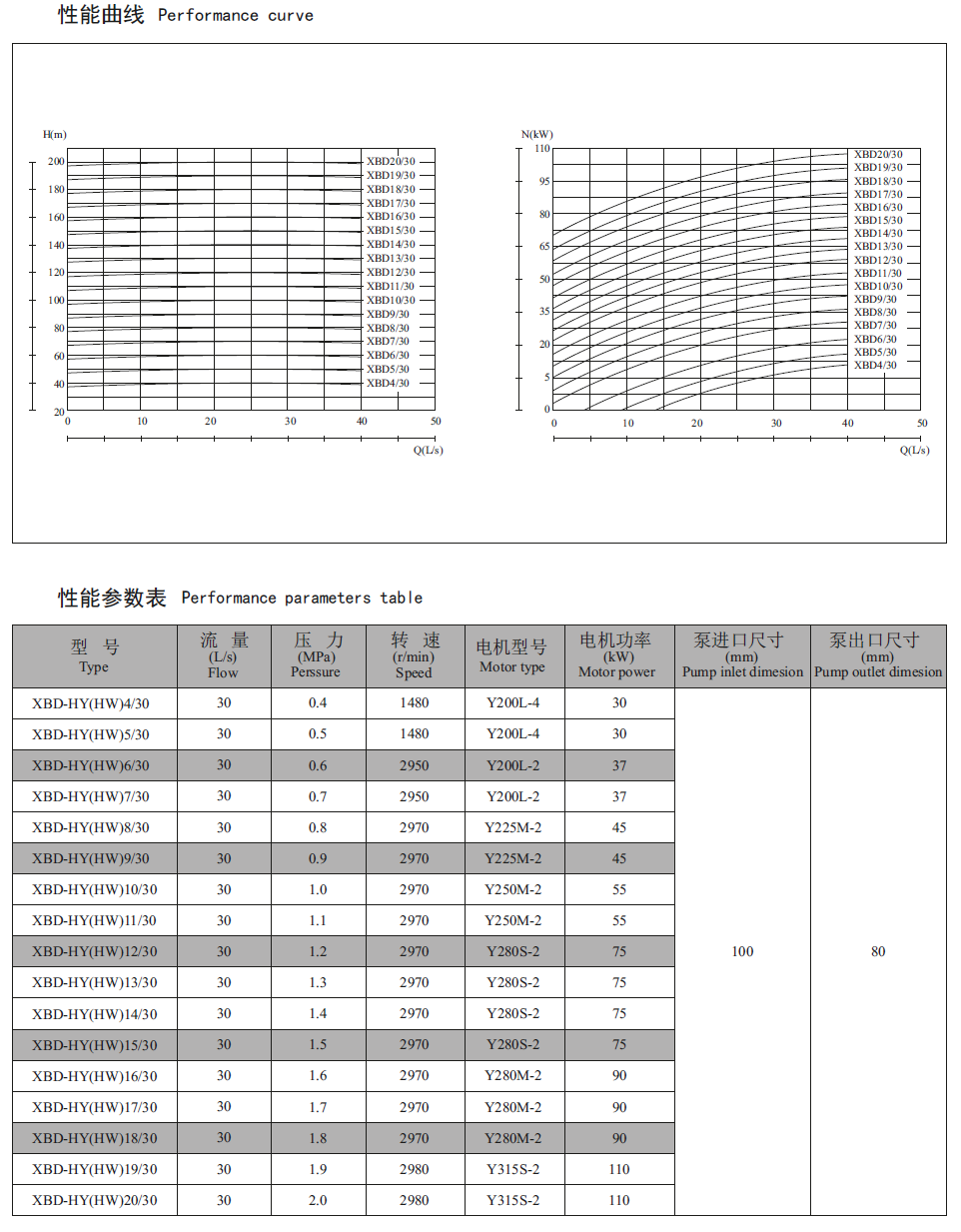

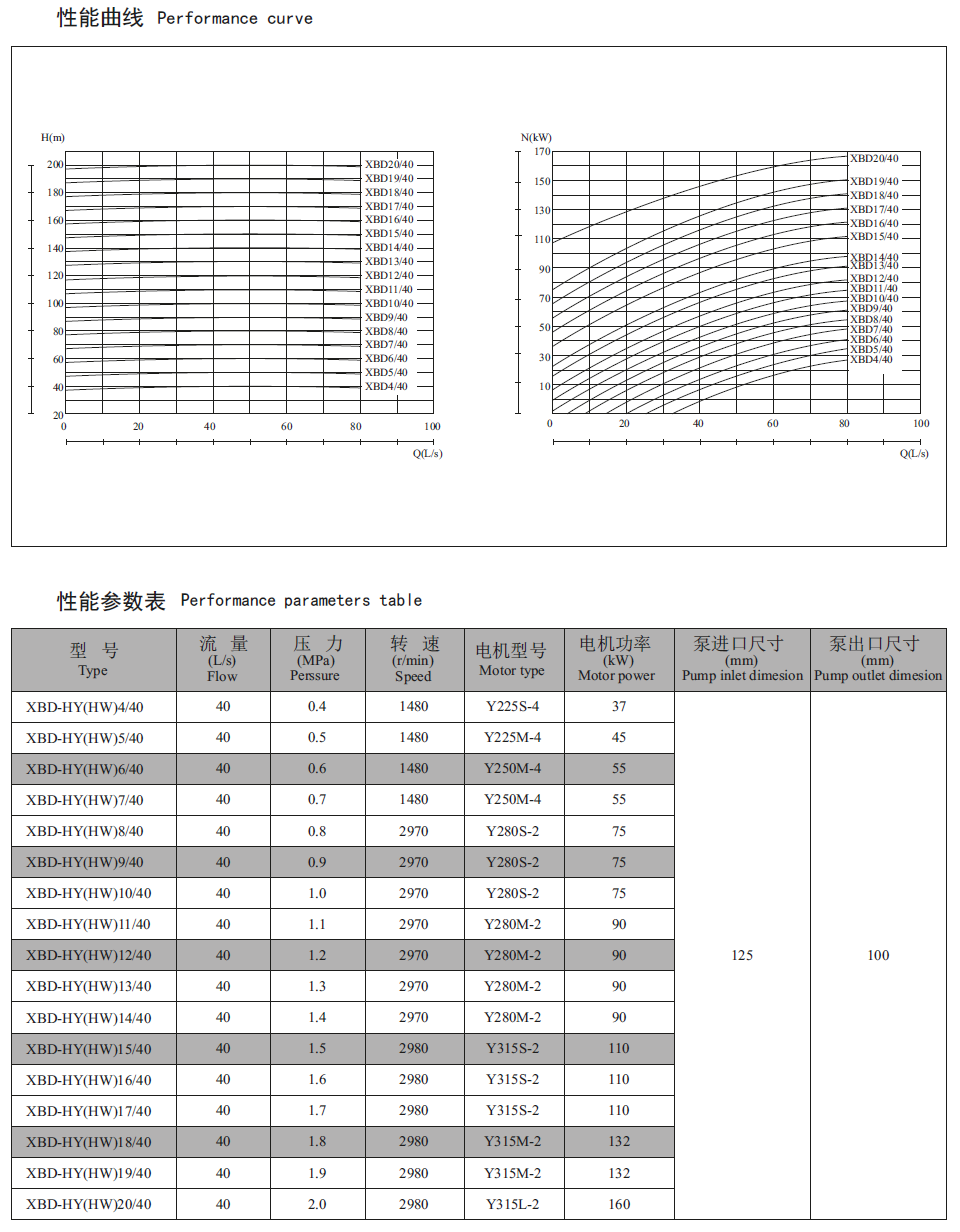

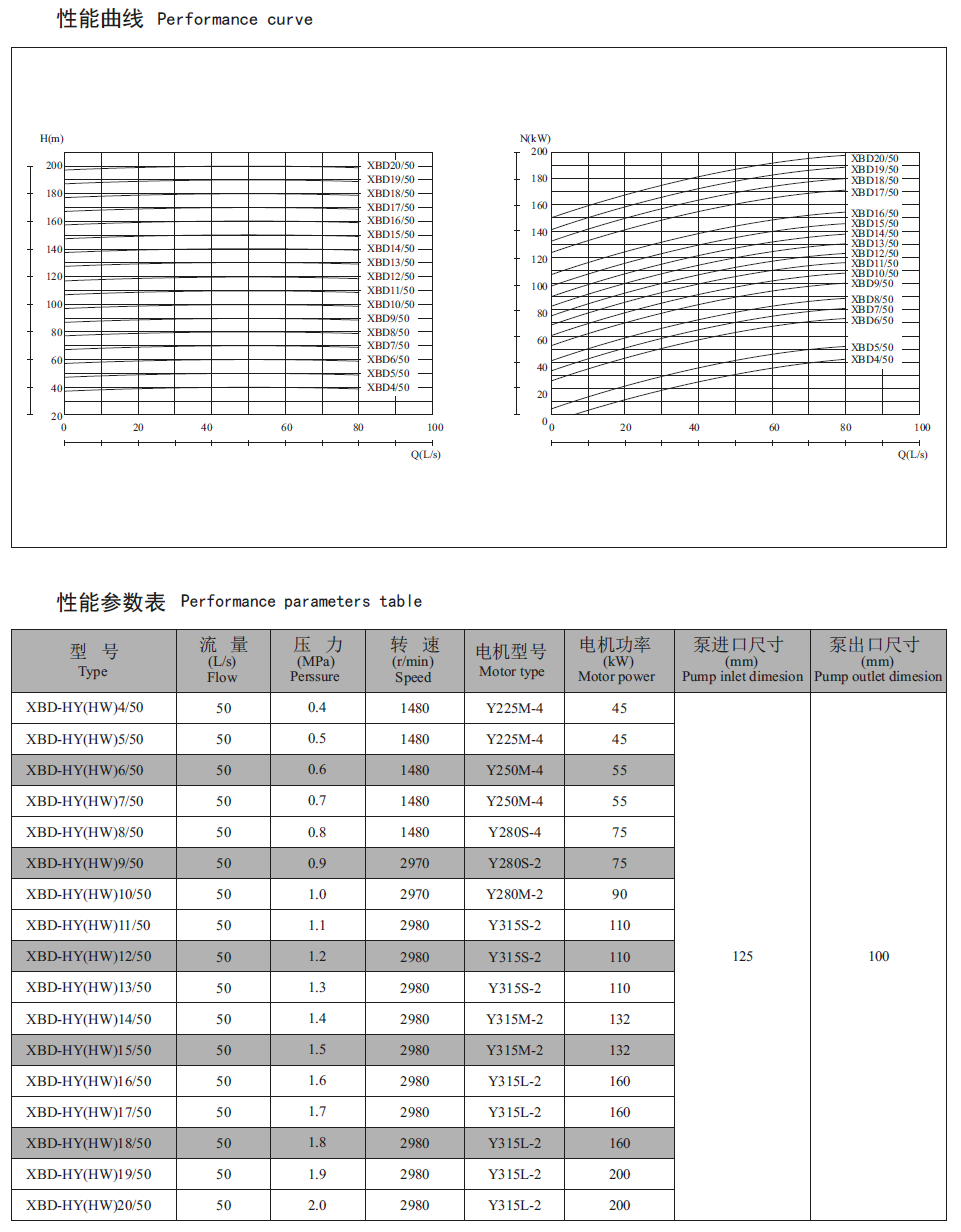

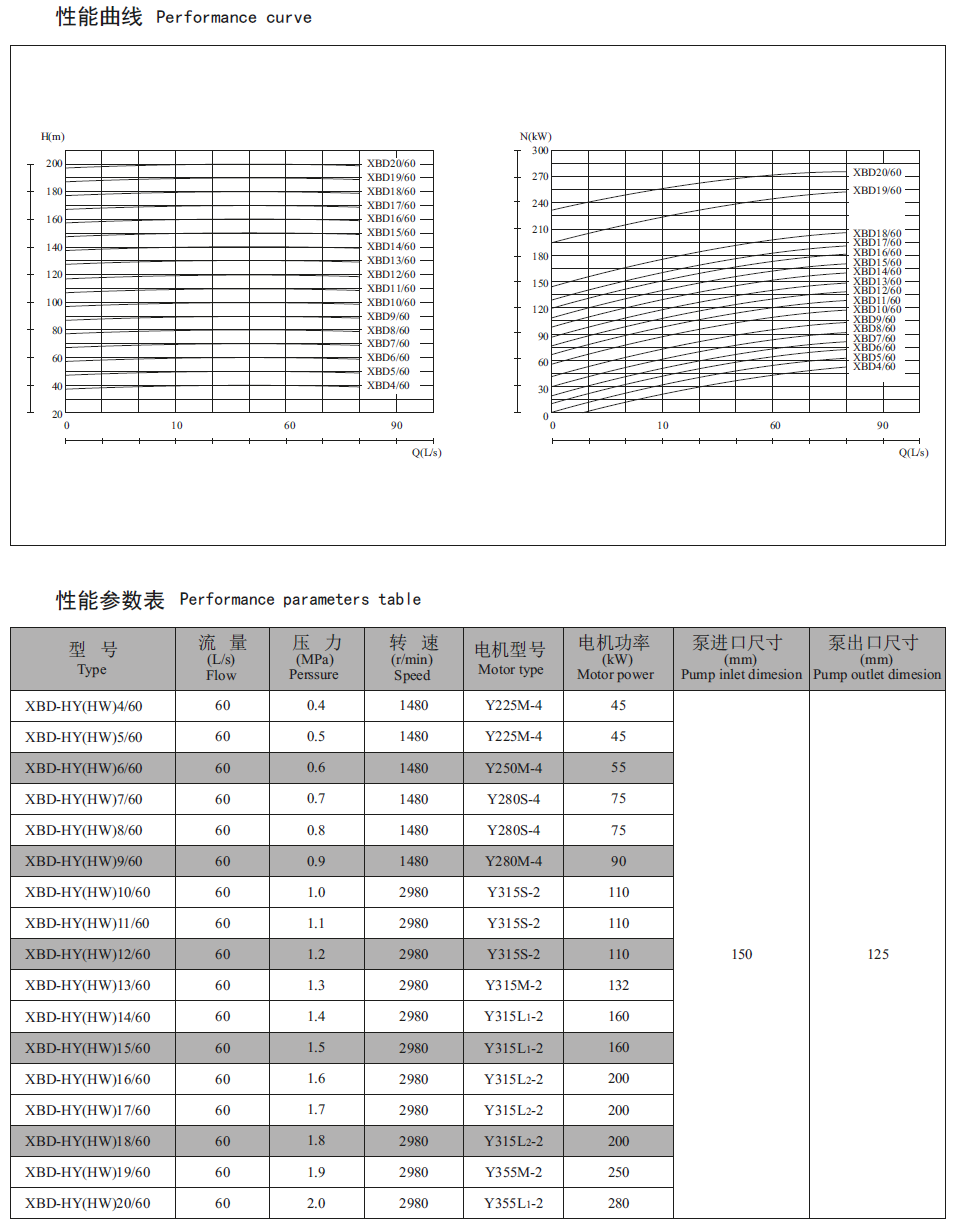

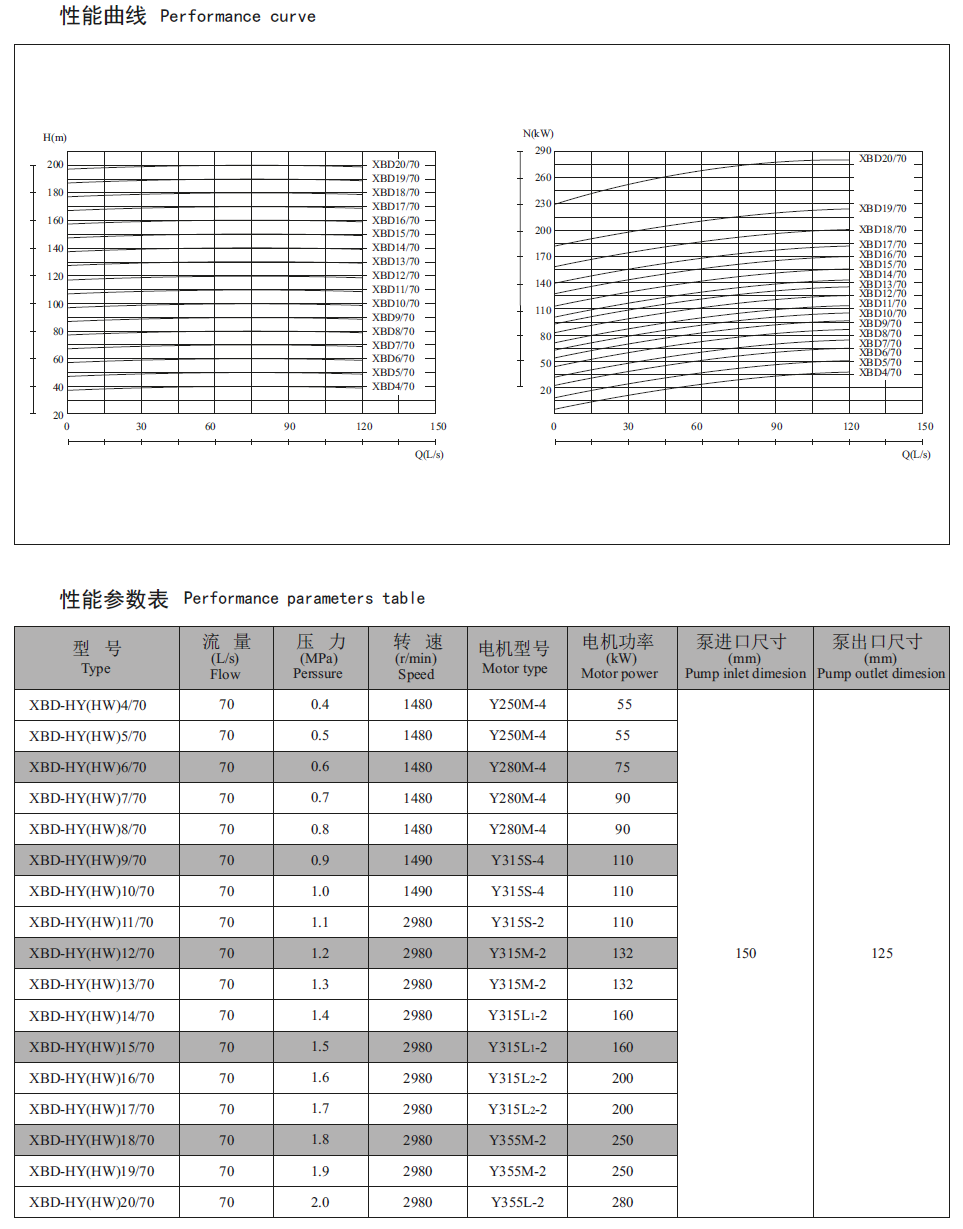

转速:1500/3000r/min(电机同步转速);

介质温度:≤80℃(清水);

流量范围:5-80L/s;

扬程范围:0.3-2.0MPa;

旋转方向:从电机端看泵为顺时针方向旋转。

Operation condition

Rotation speed: 1500/3000min (synchronized motor rotation speed);

Medium temperature: ≤80℃(clean water);

Flow scope: 5-80L/s;

Range scope: 0.3-2.0MPa;

Rotation direction: clockwise direction from the end of motor.

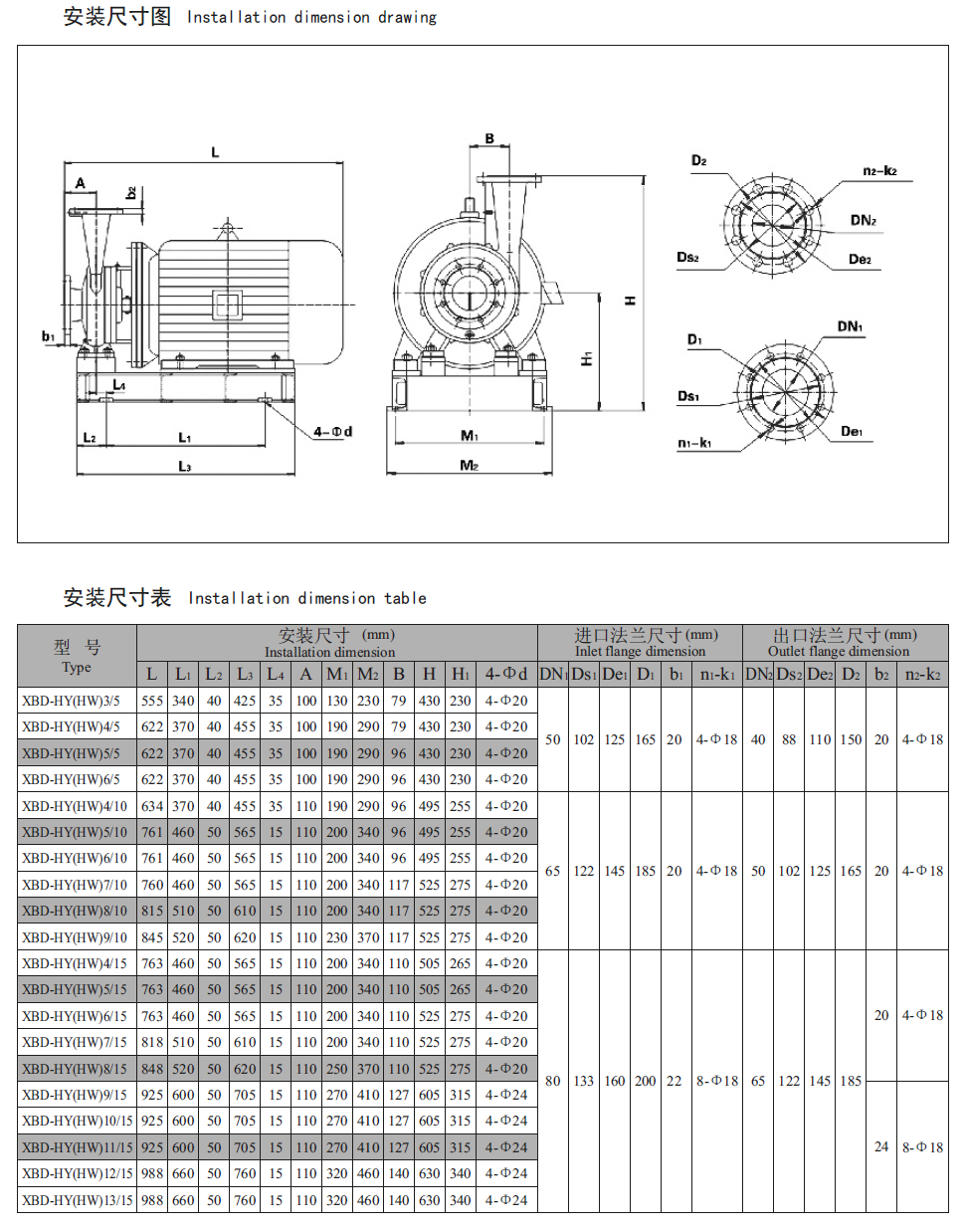

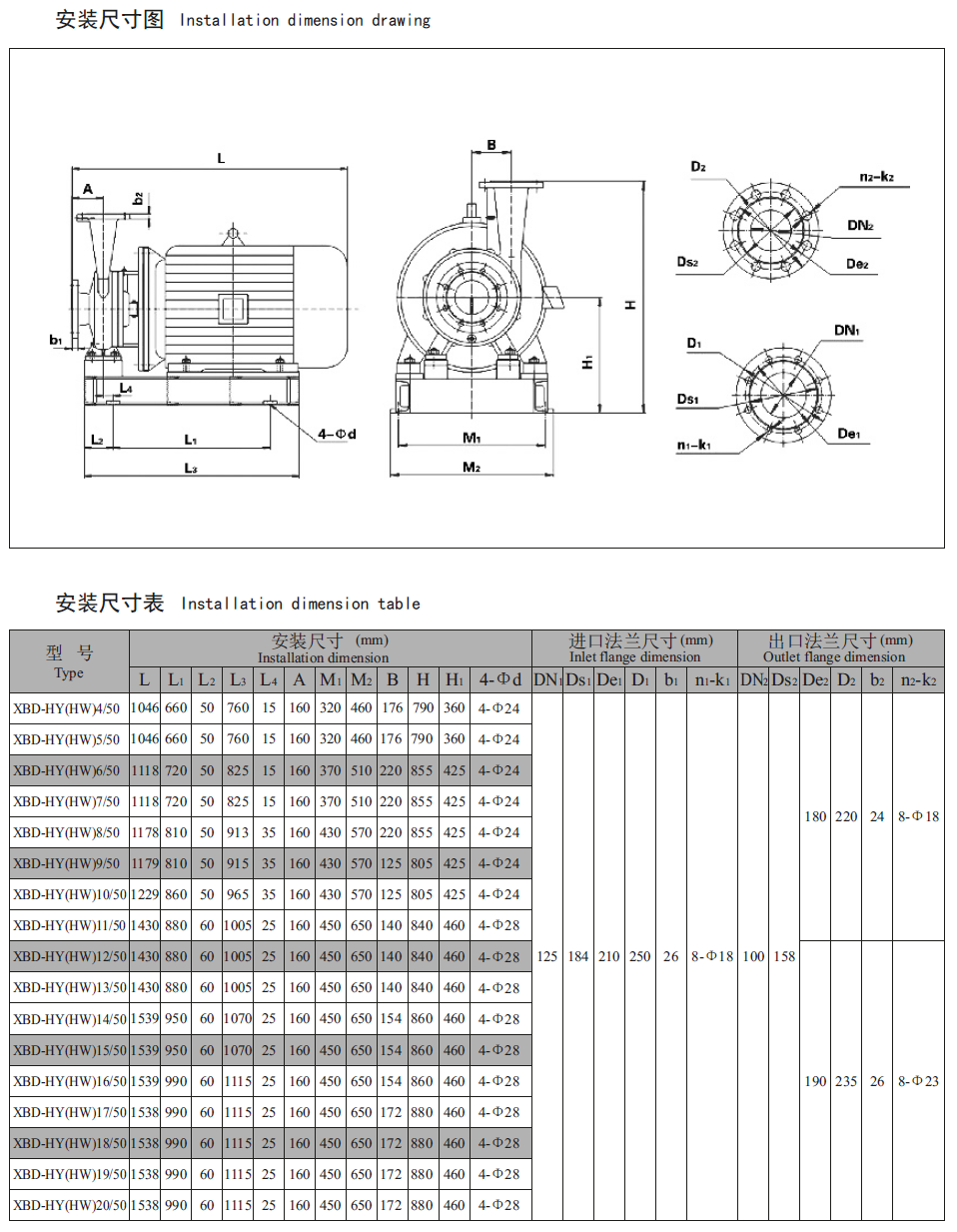

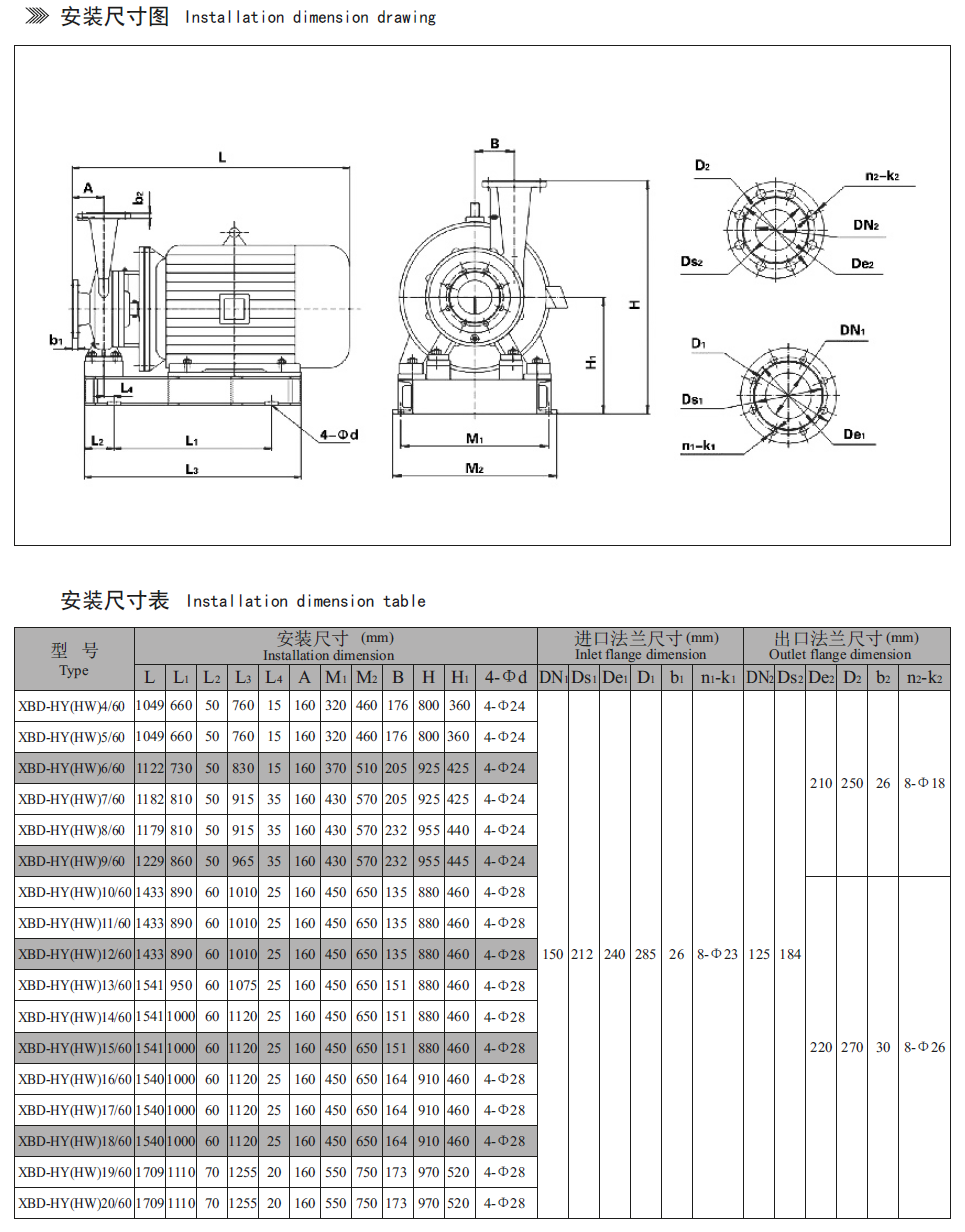

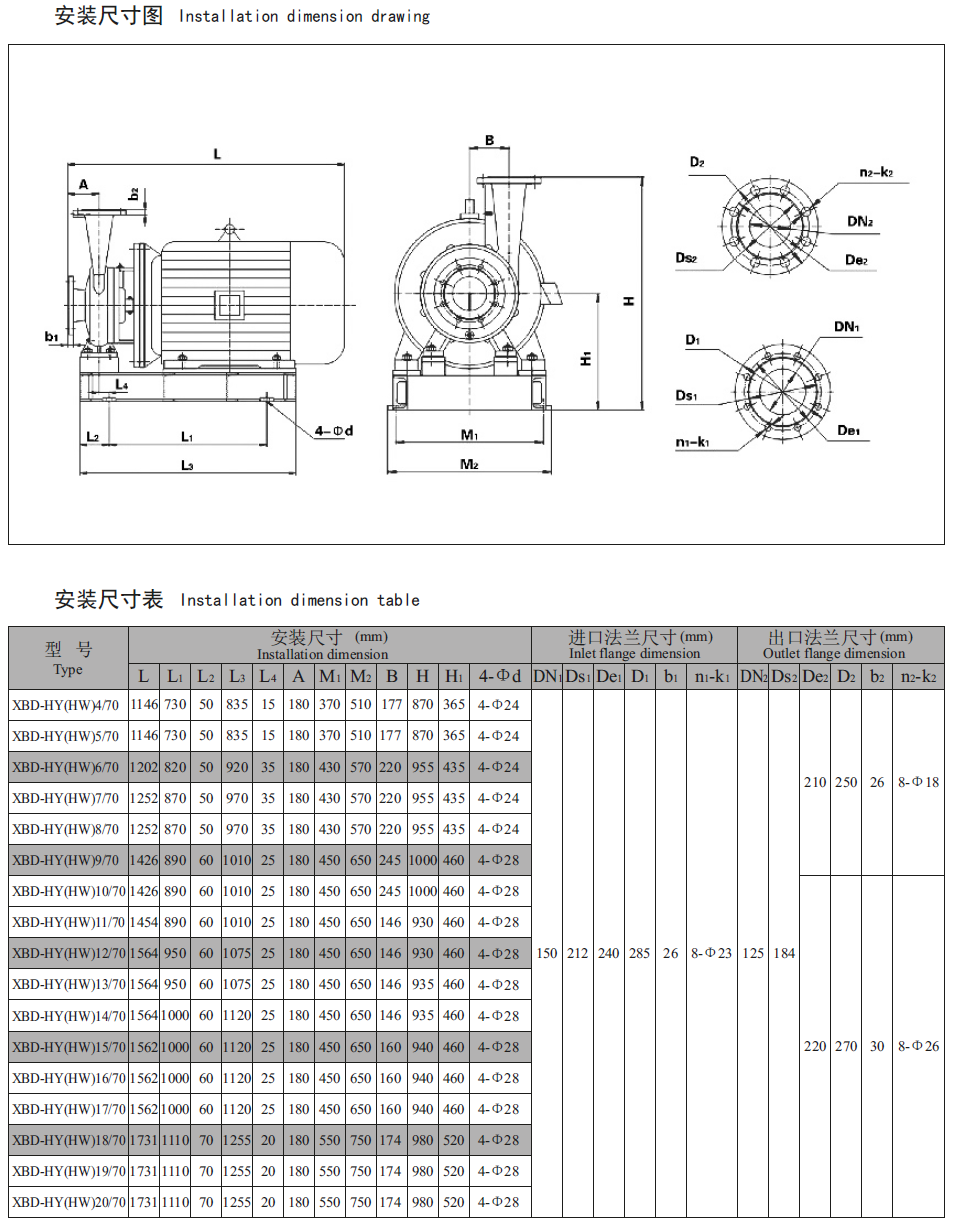

XBD系列泵安装技术要求

1.系列泵全部配有底座,当泵房设置在底层时,可用地脚螺栓直接安装在混凝土基础上。如果安装在楼层上或隔振要求较高的场合,可采用弹簧减振器和橡胶减振垫同时组合使用,减振效果更佳。水泵进出水管端必须安装橡胶挠性接头,管路系统的重量不得加在水泵上,其进出水管应用弹性吊架固定。

2.泵组水平安置,在底座下地脚螺栓孔处用金属垫块垫平,拧上螺母,灌注水泥,将底座固定稳定,安装防止底座三点接触不稳。

3.接上电机电源,电机转向应使泵按箭头指向旋转(从电机端看泵,其转向为顺时针方向)。

4.泵进出口接自来水,管径应与泵进出口直径相同,进出口管路都应有良好的对中性,长度合适,不能使泵受较大的外力。

5.启动前应作好如下准备:

a.用手转动电机轴,转动应灵活,无卡阻现象;

b.泵启动前,应使泵内充满介质;

6.机械密封泄漏量允许值为5ml/h,若认为密封泄漏量太大时,更换机械密封。

注意:机械密封动、静环端面用酒精洗干净,其余金属件用汽油清洗并用洁净的压缩空气吹干,仔细检查动、静环密封面不得有任何损伤,装配前,橡胶密封圈应涂上一层润滑油膏。

Installation technical requirements of XBD series pumps

I. All the series pumps are installed with base. Once the pump room is set at the bottom layer, anchor bolt can be adopted to install the pump directly on the concrete base; once the pump room is set in the stairs or in places with high vibration insulation requirements, spring buffer and rubber cushion can be adopted at the same time to reach better vibration attenuation effect. Rubber flexible joint must be installed for inlet and outlet water pump pipelines, the weight of pipeline system should not be added to the water pump and the inlet and outlet pipelines should be fixed with flexible hanger.

II. The pump unit should be installed horizontally. Users should adopt metal pads to flatten the anchor bolt holes under the base, fasten nuts, grout cement to make the base fastness. Efforts should be made in the installation to prevent unstable three point contact in the base.

III. The motor should rotate according to the arrow direction (clockwise direction once seeing the pump from motor end) once the motor power is switched on.

IV. Running water should be connected with pump inlet and outlet. The pipeline diameter should be same as that of pump inlet and outlet.Both inlet and outlet pipelines should have excellent neutrality, moderate length and should not impose high external pressure upon the pump.

V. Users should make the following preparations before startup:

A.Rotate the motor axis manually and the rotation should be flexible with no blockage;

B.Before start the Dump,fill the Dump with medium before startup;

Vl. The permitted seepage value of mechanical seal is 5 ml/h. The mechanical seal should be replaced once users hold that it suffers from huge seepage.

Attention: The dynamic and static ring end faces of mechanical seal should be cleaned with alcohol; other metal parts should be cleaned with gasoline and dried with clean compressed air; the dynamic and static ring end faces should be checked carefully for any damage; before assembly, a layer of lubricating grease should be coated on the rubber seal ring.