![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

一、Product Introduction

| Meaning | TYU50-32 |

| T | Code of enterprise |

| Y | Single stage centrifugal pump |

| U | Horizontal type |

| 50 | The inlet dia is 50mm |

| 32 | Nominal dia of impeller is 32mm |

Features:

1.Strong abrasion resistance:All flow parts are made from stainless steel lined with UHMW-PE. Abrasion resistance of UHMW-PE material leads the rank of all plastic materials, which four times higher than Pa66's and PTFE’s, seven times to ten times higher than cabon steel’s and stainless steel’s.

2.Strong feature of resistance to shock:The impact strength of UHMW-PE is in the first place of general engneering plastic materials, which is five times higher than ABS, and can keep stable even though in the environment of 196℃ below zero.

3.Superor anti-corrosion:The pump can transfer any kinds of corrosive medium(acid, alkali, salt) and organic solvent under certain temperature and concentration.Because of the stable chemical performance of UHMW-PE, this pump can be used on food industry as well.

5.The pump body is made of 8-20mm thickness UHMW-PE, which has merits of good anti-deformation and resistance to cracking, etc.

6.Seal type:no shaft seal and K-type dynamic seal.

7.Applicable medium:sulphuric acid under concentration of 80%, nitric acid under concentration of 50%, any concentration of hydrochloric acid and organic solvents.

Application:

1.Fertilizer industry:slute acid, waste water, sea water, fluorosilicic acid,phosphric acid fluid, etc, transfering

2.Non-ferrous metal smelting industry

3.Chemical industry:all kinds of pure liquids or fluids of sulfuric acid,hydrochloric acid,alkali, oil.

4.Chlor-alkali industry

5.Water treatment industry:pure water, high purity water, waste water, etc.

6.Iron and stainless enterprises

7.Coal industry:corrosive liquids and coal slurry transfering.

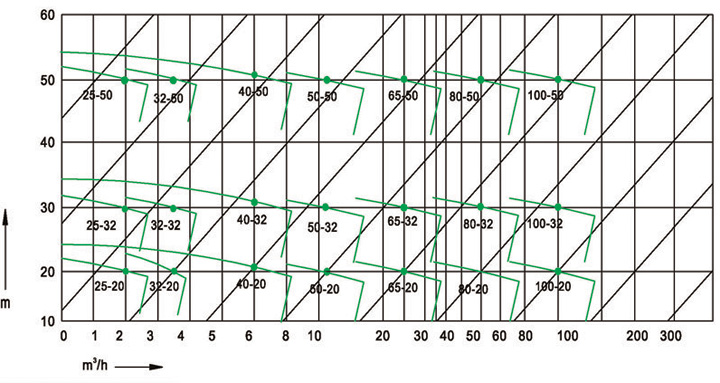

Performance range:design pressure:0.6Mpa、flow:3-120m3/h、head:15-50m、power:1.5-37kw

Applicable temperature: -20~90℃

NOTES: No idling running. Please indicate during ordering if the proportion of medium is largger than 1.3mg/cm3.

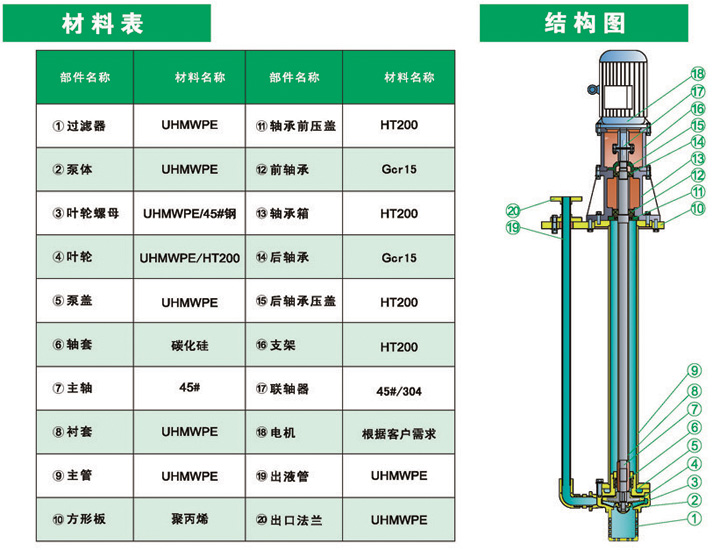

二、Structure drawing

| Part | Material | Part | Material | Part | Material |

| 1.filter | UHMAWPE | 8.bushing | UHMWPE | 15.back bearing | HT200 |

| 2.pump body | UHMWPE | 9.main pipe | UHMWPE | 16.gland of back bearing | HT200 |

| 3.impeller nut | UHMWPE/45# stainless steel | 10.square plate | Polypropylene | 17.bracket | 45#/304 |

| 4.impeller | UHMWPE/HT200 | 11.front glande of bearing | HT200 | 18.coupling | per client request |

| 5.pump cover | UHMWPE | 12.front bearing | Gcr15 | 19.motor | UHMWPE |

| 6.shaft sleeve | SSIC | 13.bearing box | HT200 | 20.outlet pipeline | UHMWPE |

| 7.main shaft | 45# | 14.back bearing | Gcr15 |

三、Performance Curve

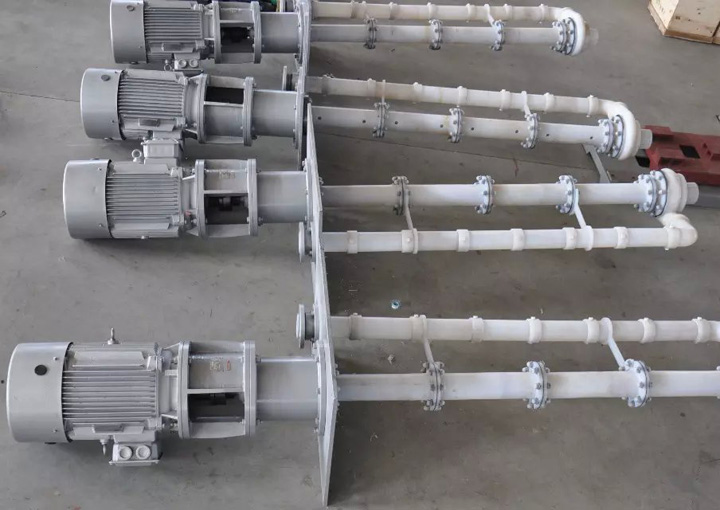

Product Photos

| Type | Speed r/min |

Flow m3/h |

Head m |

Efficiency % |

Liquid Deep m |

Inlet×Outlet mm |

Power kw |

| TYU25-20 | 2900 | 1.5 | 22 | 28 | 0-3 | 25×20 | 2.2 |

| 2 | 20 | 34.5 | |||||

| 3.2 | 18.5 | 36 | |||||

| TYU25-32 | 2900 | 1.5 | 34.3 | 24 | 0-3 | 25×20 | 3 |

| 2 | 32 | 32 | |||||

| 3.2 | 29.6 | 33 | |||||

| TYU25-50 | 2900 | 1.5 | 52.5 | 28 | 0-3 | 25×20 | 4 |

| 2 | 50 | 32 | |||||

| 3.2 | 48 | 30 | |||||

| TYU32-20 | 2900 | 2 | 22 | 40 | 0-3 | 32×20 | 2.2 |

| 3.2 | 20 | 44 | |||||

| 5.5 | 18.5 | 42 | |||||

| TYU32-32 | 2900 | 2 | 34.3 | 40 | 0-3 | 32×20 | 3 |

| 3.2 | 32 | 44 | |||||

| 5.5 | 29.6 | 42 | |||||

| TYU32-50 | 2900 | 2 | 52.5 | 32 | 0-3 | 32×20 | 5.5 |

| 3.2 | 50 | 36 | |||||

| 5.5 | 48 | 34 | |||||

| TYU40-20 | 2900 | 4.4 | 22 | 41 | 0-3 | 40×25 | 2.2 |

| 6.3 | 20 | 46 | |||||

| 8.3 | 18.5 | 43 | |||||

| TYU40-32 | 2900 | 4.4 | 34.3 | 35 | 0-3 | 40×25 | 3 |

| 6.3 | 32 | 40 | |||||

| 8.3 | 29.6 | 38 | |||||

| TYU40-50 | 2900 | 4.4 | 52.5 | 26 | 0-3 | 40×25 | 7.5 |

| 6.3 | 50 | 33 | |||||

| 8.3 | 48 | 32 | |||||

| TYU50-20 | 2900 | 7.5 | 22 | 43 | 0-3 | 50×32 | 3 |

| 12.5 | 20 | 51 | |||||

| 15 | 18.5 | 49 | |||||

| TYU50-32 | 2900 | 7.5 | 34.3 | 33 | 0-3 | 50×32 | 4 |

| 12.5 | 32 | 44.5 | |||||

| 15 | 29.6 | 46 | |||||

| TYU50-50 | 2900 | 7.5 | 52.5 | 28 | 0-3 | 50×32 | 7.5 |

| 12.5 | 50 | 37 | |||||

| 15 | 48 | 40.5 | |||||

| TYU65-20 | 2900 | 15 | 21.8 | 37 | 0-3 | 65×50 | 4 |

| 25 | 20 | 57 | |||||

| 30 | 18.5 | 60 | |||||

| TYU65-32 | 2900 | 15 | 35 | 44 | 0-3 | 65×50 | 5.5 |

| 25 | 32 | 53 | |||||

| 30 | 30 | 57 | |||||

| TYU65-40 | 2900 | 15 | 45 | 41 | 0-3 | 65×40 | 11 |

| 25 | 40 | 50 | |||||

| 30 | 35 | 53.5 | |||||

| TYU65-50 | 2900 | 15 | 53 | 41 | 0-3 | 65×40 | 15 |

| 25 | 50 | 50 | |||||

| 30 | 47 | 53.5 | |||||

| TYU80-20 | 2900 | 30 | 22.5 | 53 | 0-3 | 80×65 | 7.5 |

| 50 | 20 | 57 | |||||

| 60 | 18 | 47 | |||||

| TYU80-32 | 2900 | 30 | 36 | 52 | 0-3 | 80×65 | 11 |

| 50 | 32 | 62 | |||||

| 60 | 29 | 60 | |||||

| TYU80-40 | 2900 | 30 | 45 | 53 | 0-3 | 80×50 | 15 |

| 50 | 40 | 60 | |||||

| 60 | 35 | 58 | |||||

| TYU80-50 | 2900 | 30 | 53 | 53 | 0-3 | 80×50 | 18.5 |

| 50 | 50 | 60 | |||||

| 60 | 47 | 58 | |||||

| TYU100-20 | 2900 | 60 | 24 | 59 | 0-3 | 100×80 | 11 |

| 100 | 20 | 67 | |||||

| 120 | 16.5 | 57 | |||||

| TYU100-32 | 2900 | 60 | 36 | 56 | 0-3 | 100×80 | 18.5 |

| 100 | 32 | 67 | |||||

| 120 | 28 | 68 | |||||

| TYU100-50 | 2900 | 60 | 54 | 57 | 0-3 | 100×65 | 37 |

| 100 | 50 | 67 | |||||

| 120 | 47 | 66 |